Primary Causes of Water Chiller Flow Alarms of Laser Welder and Laser Cleaner

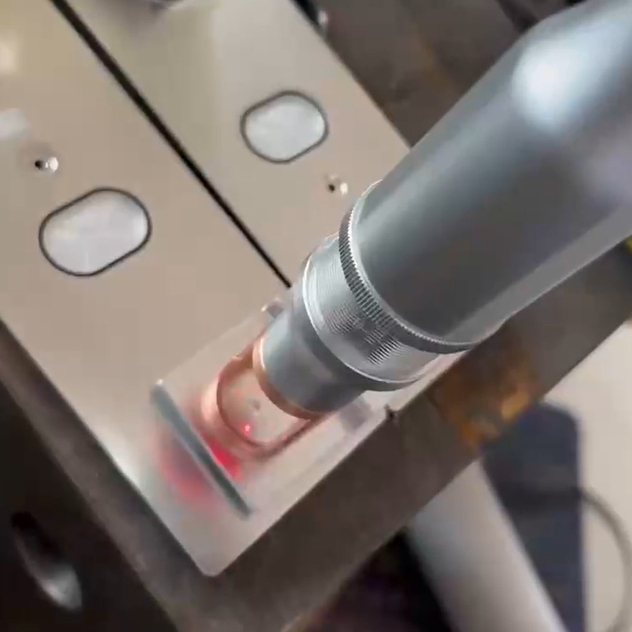

1.Low Water Level or Water Chiller Alarm: The water chiller may have insufficient water or an internal fault that triggers an alarm.

2.Feature Enabled Without Wiring: The flow monitoring feature is enabled, but no wiring is connected to relay the signal.

3.Incorrect Wiring: Faulty or improper wiring can lead to false flow