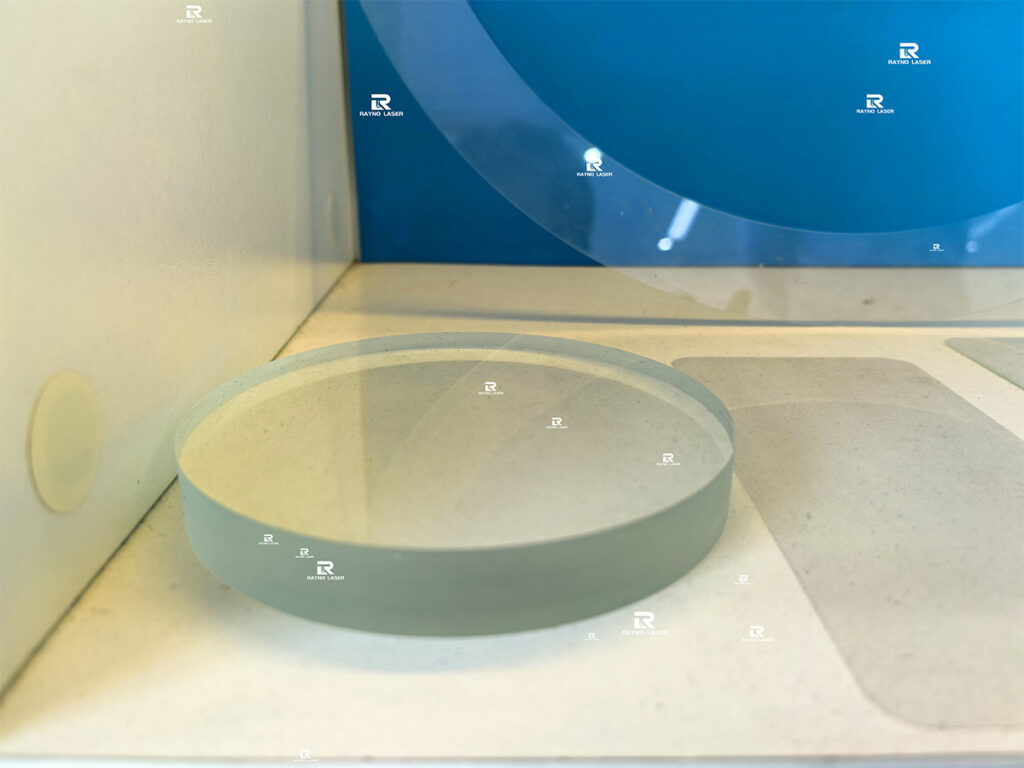

The combination of a picosecond laser and CO₂ laser is not redundant—it’s a highly efficient, complementary system that ensures both precision and clean separation of the glass. Below, we explain the principle, purpose, and effect of adding CO₂ laser technology to picosecond glass cutting.