What is a Pulsed Laser Cleaning Machine?

A pulsed laser cleaning machine uses laser pulses to remove dirt, residue, and oxidation from various surfaces. It is widely used in industries to clean molds without damaging the surface. This method provides a precise and efficient way to maintain molds, ensuring consistent production quality.

How Does the Power of a Pulsed Laser Cleaning Machine Affect Its Performance?

Pulsed laser cleaning machines are available in power levels ranging from 50W to 1000W. The higher the power, the more effective the cleaning. However, the type of laser source also influences the performance.

What Are the Two Types of Laser Sources?

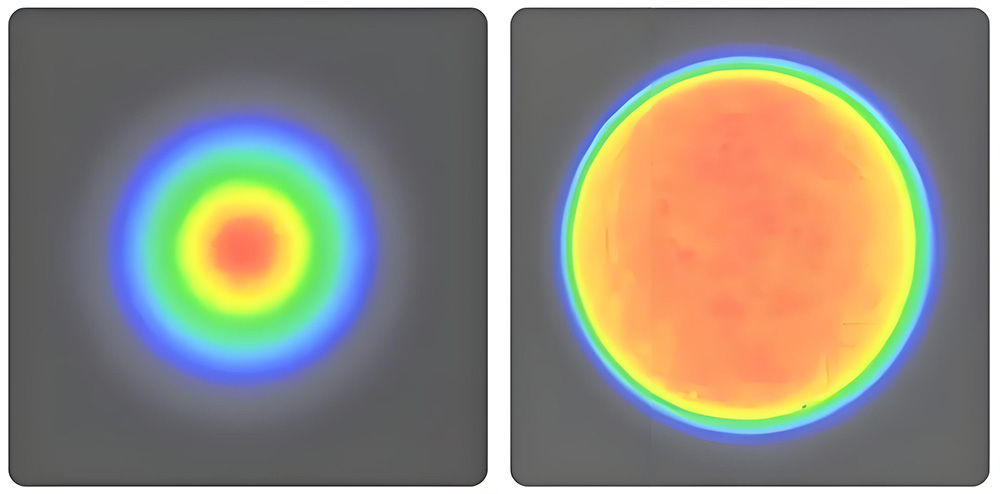

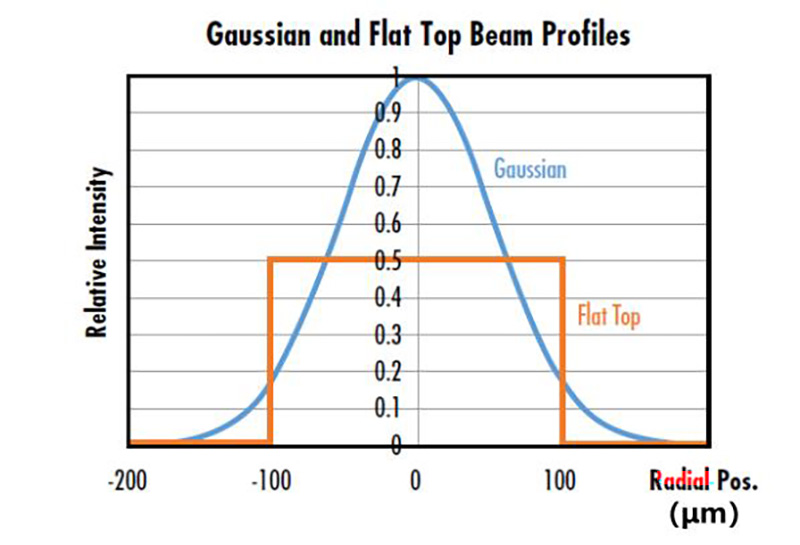

- Gaussian Beam

- Energy Concentration: The energy density is focused on a small area.

- Best Applications: Ideal for cleaning stubborn contaminants that are difficult to remove.

- Drawbacks: Can damage the base material if overused, and cleaning efficiency is slower compared to multi-mode lasers.

- Flat-Top Beam

- Energy Distribution: The energy is evenly distributed over a larger area.

- Best Applications: Suitable for removing light contaminants that are easier to clean.

- Advantages: Ensures no damage to the base material and provides faster cleaning speeds compared to single-mode lasers.

Where Can a Pulsed Fiber Laser Cleaning Machine Be Used?

Pulsed laser cleaning machines are versatile and can be used in various mold-cleaning applications, including:

- Injection Mold Cleaning: Removes plastic residues and other contaminants without scratching or degrading the mold surface.

- Blow Mold Cleaning: Effectively cleans blow molds used in bottle manufacturing.

- Glass Bottle Mold Cleaning: Ensures clean molds for precise glass shaping.

- Tire Mold Cleaning: Safely removes residues from intricate tire mold designs.

How Does Laser Cleaning Compare to Traditional Cleaning Methods?

Traditional Methods:

- Dry Ice Blasting: Requires consumables (dry ice pellets), which incur continuous costs. The process is also less environmentally friendly due to the production and disposal of dry ice.

- Chemical Cleaning: Involves hazardous substances that can harm the environment and may damage the mold over time.

- Abrasive Cleaning: Risks scratching or wearing down the mold material.

Laser Cleaning:

- Efficiency: Offers faster cleaning speeds for various mold types.

- Environmental Impact: Requires no consumables and generates no harmful waste.

- Surface Protection: Effectively cleans without damaging the mold’s base material.

How Is Mold Cleaning Done Using a Pulsed Laser Machine?

The process involves directing the laser beam onto the mold’s surface. The laser energy interacts with the contaminants, breaking them down into particles that can be easily removed. Depending on the type of laser source and mold, the process can be tailored for optimal results.

For example:

- For tough contaminants: A Gaussian beam may be more suitable.

- For delicate surfaces: A flat-top beam ensures safe and efficient cleaning.

Why Choose a Pulsed Laser Cleaning Machine for Mold Maintenance?

- Improves Productivity: Clean molds help maintain high-quality production with fewer defects.

- Reduces Costs: No need for consumables like dry ice or chemicals.

- Supports Sustainability: A clean and efficient solution with minimal environmental impact.

Pulsed laser cleaning machines offer a practical and reliable solution for maintaining molds used in industries such as plastics, glass, and rubber. By tailoring the laser power and beam type to the specific cleaning task, these machines ensure effective results without compromising the integrity of the mold.

Please contact us for suitable model or further information.