Outline:

- What is Laser Cleaning?

- How Does Laser Cleaning Work?

- What Are the Advantages of Laser Cleaning Compared to Traditional Cleaning Methods?

- Precision and Control

- Environmental Benefits

- Cost-Effectiveness and Efficiency

- Non-abrasive and Non-contact Process

- What Industries Can Benefit from Laser Cleaning?

- Conclusion: Why Choose Laser Cleaning?

- Laser Cleaning Compare with Other cleaning Methods

The Advantages of Laser Cleaning

1. What is Laser Cleaning?

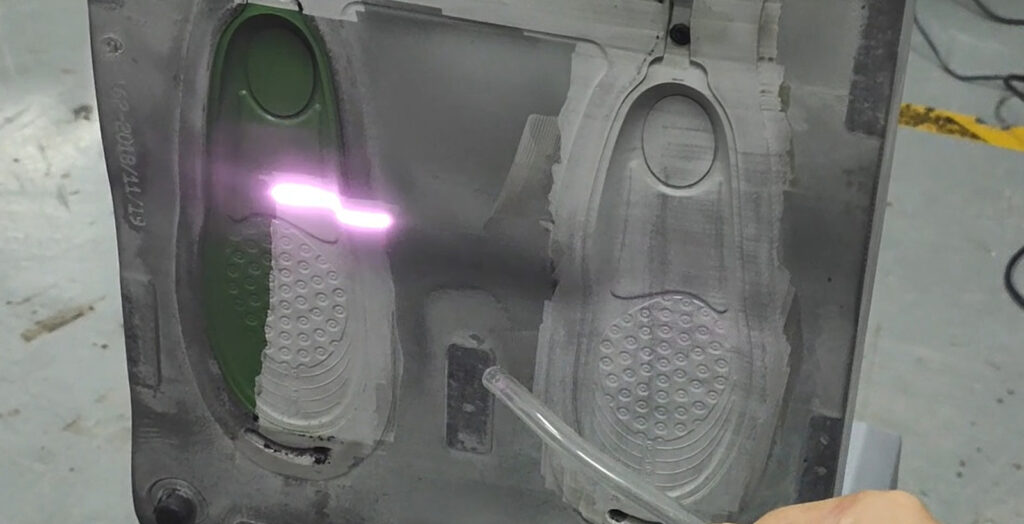

Laser cleaning is an advanced, non-contact cleaning method that uses high-intensity laser beams to remove contaminants, rust, paint, oxides, and other unwanted materials from surfaces. It is a highly precise and efficient technology that has gained popularity across various industries due to its ability to deliver superior cleaning results without damaging the underlying material.

2. How Does Laser Cleaning Work?

Laser cleaning works by directing a focused laser beam onto the surface to be cleaned. The laser energy is absorbed by the contaminants, causing them to vaporize or turn into plasma, which is then removed from the surface. The process is controlled by adjusting parameters such as laser power, pulse duration, and wavelength, ensuring that only the unwanted material is removed while the base material remains intact.

3. What Are the Advantages of Laser Cleaning Compared to Traditional Cleaning Methods?

Precision and Control:

One of the most significant advantages of laser cleaning is its precision. Unlike traditional methods such as sandblasting, chemical cleaning, or manual scrubbing, laser cleaning can target specific areas without affecting the surrounding material. This level of control is particularly beneficial for delicate or complex components where even minor damage can be costly.

Environmental Benefits:

Laser cleaning is an environmentally friendly alternative to traditional cleaning methods. It does not require the use of harmful chemicals, solvents, or abrasive materials, which can pose health risks and contribute to environmental pollution. Additionally, the process generates minimal waste, as the removed contaminants are typically vaporized and can be easily collected using filtration systems.

Cost-Effectiveness and Efficiency:

While the initial investment in laser cleaning equipment may be higher than traditional methods, the long-term cost savings are substantial. Laser cleaning reduces the need for consumables such as chemicals, abrasives, and replacement parts. It also minimizes downtime, as the process is fast and requires little to no post-cleaning treatment. Moreover, the precision of laser cleaning reduces the risk of damage, which can lead to costly repairs or replacements.

Non-abrasive and Non-contact Process:

Traditional cleaning methods often involve physical contact with the surface, which can lead to wear and tear over time. Laser cleaning, on the other hand, is a non-contact process that does not exert any mechanical force on the material. This makes it ideal for cleaning sensitive or fragile surfaces, such as historical artifacts, electronic components, or precision-engineered parts.

4. What Industries Can Benefit from Laser Cleaning?

Laser cleaning is versatile and can be applied across a wide range of industries, including:

- Automotive: Removing rust, paint, and coatings from car parts without damaging the metal.

- Aerospace: Cleaning turbine blades, engine components, and other critical parts.

- Manufacturing: Preparing surfaces for welding, bonding, or coating applications.

- Cultural Heritage: Restoring historical artifacts and monuments with precision.

- Electronics: Cleaning delicate components without causing electrostatic discharge or physical damage.

5. Conclusion: Why Choose Laser Cleaning?

Laser cleaning offers a host of advantages over traditional cleaning methods, including precision, environmental friendliness, cost-effectiveness, and the ability to clean delicate surfaces without damage. As industries continue to seek more efficient and sustainable solutions, laser cleaning stands out as a cutting-edge technology that can meet these demands. By investing in laser cleaning equipment, businesses can improve their operational efficiency, reduce environmental impact, and achieve superior cleaning results.

In conclusion, laser cleaning is not just a cleaning method; it is a transformative technology that is reshaping the way industries approach surface preparation and maintenance. Whether you are in automotive, aerospace, manufacturing, or any other industry, laser cleaning can provide the precision and efficiency you need to stay ahead in today’s competitive market.

Comparison of Laser Cleaning with Traditional Cleaning Methods

| Cleaning Method | Laser Cleaning | Chemical Cleaning | Mechanical Grinding | Dry Ice Cleaning | Ultrasonic Cleaning |

|---|---|---|---|---|---|

| Cleaning Method | Laser, non-contact | Chemical cleaning agent, contact type | Sandpaper, contact | Dry ice, non-contact | Cleaning agent, contact type |

| Workpiece Damage | No | Yes | Yes | No | No |

| Cleaning Efficiency | High | Low | Low | Medium | Medium |

| Consumables | Only electricity | Chemical cleaning agent | Sandpaper, grinding wheel | Dry ice | Special cleaning agent |

| Cleaning Effect | Spotlessness | General, uneven | General, uneven | Excellent, uneven | Excellent, small range |

| Safety/Environmental Protection | No pollution | Polluted | Polluted | No pollution | No pollution |

| Manual Operation | Simple operation, handheld or automated | The process flow is complex, and the requirements for operators are high | Labor-intensive, protective measures are required | Simple operation, handheld or automated | Simple operation, need to manually add consumables |

| Cost Input | High initial investment cost, no consumables, low maintenance cost | Low initial investment and high cost of consumables | High initial investment and low cost of consumables | The initial investment is medium, and the cost of consumables is high | Low initial investment and high cost of consumables |

This comparison highlights the superior performance of laser cleaning in terms of efficiency, environmental impact, and overall cost-effectiveness. By choosing laser cleaning, businesses can achieve better cleaning results while minimizing their environmental footprint and operational costs.

If you are looking for a suitable laser cleaning machine, please contact us freely. We will suggest the right one according to your needs.