If you’ve ever used a handheld laser welding machine, you know one major challenge that keeps coming back: nitrogen supply. It’s not just about the cost—it’s the logistics, the tanks, the refills, and the constant interruptions. Every time you set up a new project or move to a different worksite, sourcing nitrogen becomes an added layer of complexity.

But what if you didn’t have to worry about nitrogen anymore?

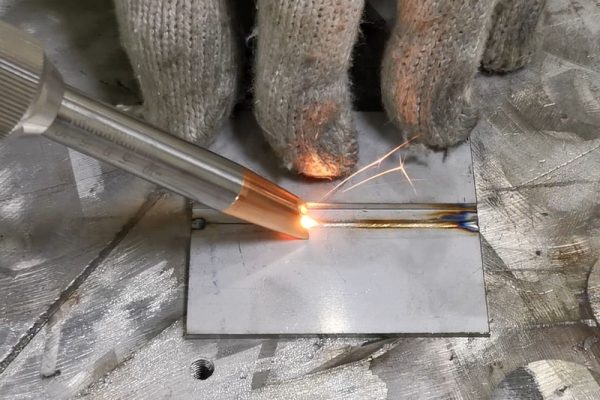

Welcome to a new era of laser welding: a truly integrated solution that combines a nitrogen generator and handheld laser welding system into one compact, efficient machine. With this innovation, you can wave goodbye to external gas procurement and hello to a self-sustaining, plug-and-play welding experience.

The Problem: Nitrogen Dependency

In laser welding, nitrogen plays a key role in shielding the weld zone from oxidation and contamination. It’s essential—but traditionally, it’s a headache. Whether you’re running a small workshop or operating at a larger scale, relying on external nitrogen sources means:

- Renting or buying nitrogen cylinders

- Coordinating deliveries and returns

- Monitoring supply levels constantly

- Interruption of work due to nitrogen shortage

- Safety risks with storing high-pressure cylinders

And let’s not forget the costs—both direct and hidden—involved in ongoing gas purchases, logistics, and downtime.

The Solution: Built-in Nitrogen Generation

This new integrated machine eliminates all of that. It combines a nitrogen generator, control system, and handheld laser welding unit into one streamlined package. All you need is filtered air and a compact air compressor (6–8kg pressure)—no external nitrogen tanks required.

Here’s how it works:

- The nitrogen generator draws purified air from the supplied air compressor

- It separates the nitrogen on the spot

- The system feeds nitrogen directly into the laser welding head

- Real-time gauges display pressure, purity, and flow rate

- You get clean, consistent, high-purity nitrogen—anytime, anywhere

This is true on-demand nitrogen, produced and used right where you need it.

Key Features at a Glance

✅ Integrated Design – Combines welding control, nitrogen generation, and monitoring into one machine

✅ No More Gas Tanks – Just connect a small air compressor with an oil-water separator

✅ Real-Time Monitoring – Built-in gauges show nitrogen pressure, purity, and flow rate

✅ Standard Power – Runs on standard 220V single-phase, 50Hz or 60Hz

✅ Low Cost, High Convenience – Huge long-term savings with no gas refills or delivery

✅ Compact & Mobile – Perfect for workshops, fieldwork, and flexible production lines

Easy Setup, Easier Operation

The simplicity of setup is one of the key attractions of this unit. Here’s what you need:

- A filtered air source — any small air compressor capable of 6–8kg of pressure

- A 220V single-phase power supply — no special wiring or industrial power needed

- Plug in the machine, wait the gas purity to 99.99% and you’re ready to weld

No special training is required. The control panel is intuitive, the nitrogen system runs in the background, and the operator can focus entirely on precision welding.

Who Benefits Most?

This solution is perfect for a wide range of users, including:

- Small and medium-sized manufacturers who want to reduce operating costs

- Job shops that need mobility and flexibility without gas delivery constraints

- Repair and maintenance teams working in variable locations

- Welders in remote areas where bottled nitrogen is expensive or unavailable

- Anyone tired of dealing with nitrogen logistics

Real-World Impact: Saving Time, Cutting Costs

Let’s talk numbers. Over the course of a year, the average small operation might spend thousands on nitrogen gas—especially when factoring in delivery, cylinder rental, and potential downtime.

With this machine, you generate your own nitrogen as needed. There’s no recurring purchase, no waste, and no waiting. Over time, the savings are substantial—and they start on day one.

And it’s not just cost. It’s efficiency. You’ll spend less time managing consumables and more time getting quality welds done.

One Response

Nitrogen is indeed crucial in laser welding to prevent oxidation and contamination. Relying on external nitrogen sources can be costly and inefficient, especially for small workshops. Generating your own nitrogen with this machine seems like a practical and cost-effective solution. The simplicity of the setup and the potential savings make it an attractive option. How does the machine ensure consistent nitrogen purity for different welding applications?