Handheld Laser Welding Machine with Built-in Nitrogen Generator

If you’re in the metal fabrication, automotive, aerospace, or equipment maintenance industries, you know the headaches of traditional welding setups: separate gas tanks, bulky cooling systems, high operating costs, and constant maintenance.

Now a welding system that eliminates those problems in one compact, intelligent, and energy-efficient solution.

FOB Reference Price: Get Latest Price

PRODUCT DESCRIPTION

What Makes It Different?

At its core, this machine combines three technologies into one unit:

-

A high-power handheld fiber laser welder

-

A nitrogen generation system (≥99.9% purity)

-

Combines nitrogen gas and laser control system in one machine

This seamless integration creates a next-generation solution for high-precision, low-maintenance welding.

Key Features and Benefits

1. Fully Integrated Design

Why buy and connect three machines when one can do it all? This compact unit houses everything you need to weld with nitrogen protection—laser source, gas generation, and cooling—inside a single cabinet.

-

Saves space on your workshop floor

-

Reduces complexity in installation

-

Minimizes troubleshooting and maintenance

-

No more juggling gas tanks or external chillers

2. Built-in Nitrogen Generation (≥99.9% Purity)

2. Built-in Nitrogen Generation (≥99.9% Purity)

Nitrogen plays a crucial role in shielding the weld pool and preventing oxidation—especially for stainless steel, aluminum, and other active metals.

-

Generates nitrogen on demand from filtered air

-

Eliminates recurring costs of bottled gas

-

Delivers high-purity nitrogen continuously

-

Keeps your welds clean, strong, and visually perfect

You’ll also save 30%–50% on nitrogen costs compared to traditional bottled gas.

3. Air Cooling, More Compact Machine Size

3. Air Cooling, More Compact Machine Size

Forget antifreeze, water tanks, and leakage risks. The efficient air-cooling system keeps your machine operating safely and steadily, even in challenging environments.

-

Lower maintenance than water cooling

-

Ideal for low-temperature or water-scarce locations

-

Reduces long-term wear and extends machine life

-

Energy-efficient and environmentally friendly

Superior Welding Performance

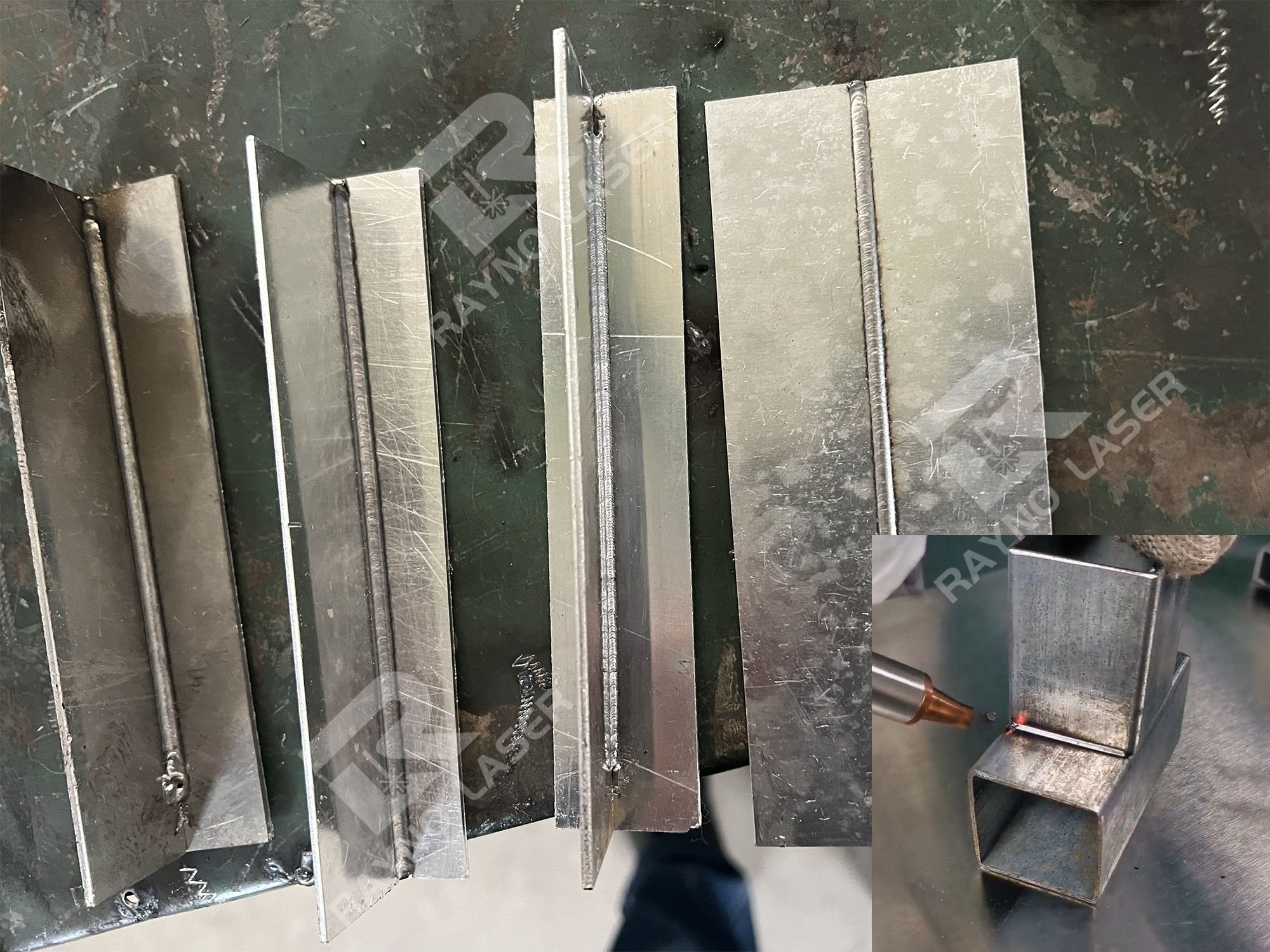

Faster Speeds, Cleaner Results

This handheld fiber laser welder outperforms traditional TIG and MIG welding in both speed and finish.

-

Increases productivity by 30–50%

-

Minimal thermal deformation—ideal for thin sheets

-

Welds a variety of metals: carbon steel, stainless steel, aluminum, copper, and more

-

Handles dissimilar metal joints with ease

Smooth, Beautiful Welds

Thanks to the real-time nitrogen protection, the welds are free from oxidation stains, pores, or cracks. Most projects won’t even require polishing afterward, saving you valuable labor time.

Intelligent Control System

This isn’t just a welding tool—it’s a smart machine. The system features a touch-screen interface with built-in automation and monitoring, so even operators with minimal experience can achieve excellent results.

Key functions include:

-

One-button control of laser power, speed, and nitrogen flow

-

Real-time monitoring of nitrogen purity, gas pressure, and machine temperature

-

Automatic alarms in case of abnormal conditions

-

Compatibility with leading software systems like SUP, RELFAR, and RAYTOOLS

With built-in diagnostics and safety checks, the system helps reduce downtime and boosts operator confidence.

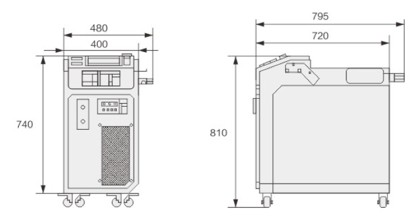

Technical Overview

-

Laser Power Options: 700W / 1200W / 1500W / 2000W

-

Nitrogen Flow Rate: 20 NL/min

-

Nitrogen Purity: 95–99.99%

-

Cooling Method: Air-cooled (no water required)

-

Voltage: 220V, single-phase, 50/60Hz

-

Weight: Approx. 73kg

-

Wire Feeding Support: 0.8–2.0 mm

-

Operating Environment: -20°C to 45°C, 10–85% humidity

All components are built with Rayno Laser’s high-quality standards, ensuring performance and durability.

Application Versatility

This system is ready to take on a wide range of applications across industries:

-

Metal fabrication

-

Kitchen and sanitary ware

-

Automotive manufacturing and repair

-

Elevator and appliance production

-

Aerospace and construction

-

Advertising signage

-

Battery and electronics assembly

Its mobility, ease of use, and low maintenance make it especially suitable for small to medium-sized factories, workshops, and repair centers.

After-Sales Support

With Rayno Laser, you’re not just buying a machine—you’re getting full professional support:

-

1-year warranty on the entire unit

-

2-year warranty on the laser source

-

Free training at our facility or online

-

24/7 support via WhatsApp, Zoom, email, or phone

-

On-site technical service available if needed (travel costs borne by buyer)

We provide a complete English user manual and operation video to help you get started right away.

TECHNICAL PARAMETERS

Additional information

| Model | RN-AWH700 | RN-AWH1200 | RN-AWH1500 | RN-AWH2000 |

|---|---|

| Laser Power | 1200W, 1500W, 2000W, 700W |

| Nitrogen purity | 95-99.99% |

| Laser-wavelength | 1080+10 nm |

| Laser Cable Length | 10 m |

| Aiming and Positioning | Red Beam |

| Cooling Method | Air Cooling |

| Working Voltage | 220±20V,AC,PE,50/60Hz |

| Power Consumption | 7KW, 9KW |

| Package Weight | ~100KG |

VIDEO

SAMPLE DISPALY

Send your messages to the supplier

Get additional product information or technical support. Our team is always available to provide you with the necessary guidance and solutions.