In today’s manufacturing world, flexibility and efficiency are no longer optional—they’re essential. Customers demand cleaner welds, faster processing, and greater precision, all while keeping production costs under control. Traditional welding or cutting tools can’t always keep up with these challenges. That’s why Rayno Laser introduces the 6-in-1 Handheld Laser Welding Machine, a breakthrough solution that combines six powerful functions into a single, portable system will on sale soon.

One Machine, Six Functions

Unlike conventional laser welding tools that only serve a single purpose, this machine redefines versatility. With a simple switch of modes, operators can choose from six distinct functions:

- Laser Welding – High-speed, low-deformation welding suitable for a wide range of metals.

- Laser Cleaning – Non-contact cleaning that removes rust, paint, or contaminants from metal surfaces.

- Seam Cleaning (Post-Weld Cleaning) – A specialized mode to clean weld seams instantly, improving appearance and preventing oxidation.

- Energy-Storage Welding – Enhanced penetration and strength for thicker materials or challenging applications.

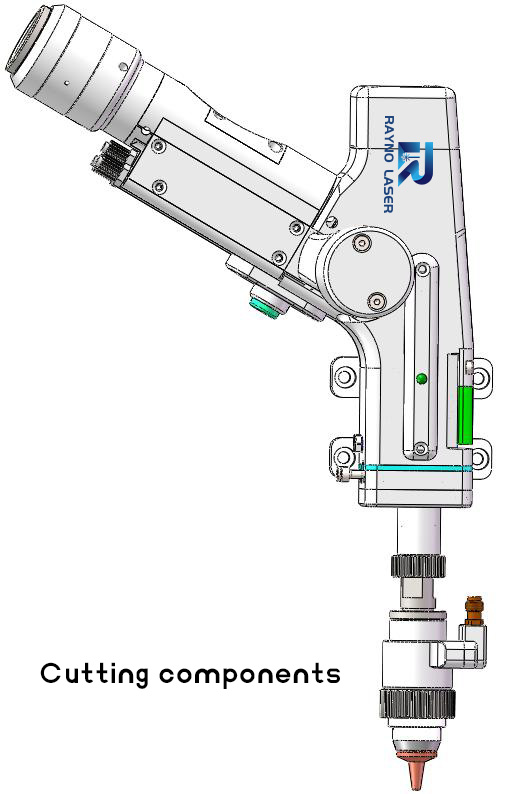

- Manual Cutting – Flexible handheld laser cutting for simple cuts and on-site adjustments.

- Automatic Cutting (Newly Added) – Precision-guided cutting for smoother edges, tighter tolerances, and improved efficiency in repetitive tasks.

The upgrade from the previous 5-in-1 system to this 6-in-1 version adds a major advantage: automatic cutting. This new capability enables higher accuracy, greater repeatability, and cleaner results compared to manual cutting—perfect for users who need both flexibility and precision in one solution.

Technical Highlights

The 6-in-1 handheld laser welding head is engineered for durability, precision, and ease of use. Some key parameters include:

- Supported Power Levels: 1500W / 2000W / 3000W

- Fiber Interface: QBH

- Wavelength Range: 1070 ± 20 nm

- Rated Power Handling: ≤ 3000W

- Collimation Focal Length: 40 mm

- Focusing Focal Length: 150 mm

- Oscillation Patterns: Line, Circle, Figure-8, Spiral, Triangle, Double-Circle, etc.

- Focal Adjustment Range: -10 mm ~ +10 mm

- Beam Adjustment Range: 0 ~ 5 mm

- Assist Gas Pressure: ≤ 1 MPa

With such versatility, the machine adapts to different materials, thicknesses, and applications seamlessly.

Key Advantages

1. Multi-Functionality in One Unit

Why invest in multiple machines when one system does it all? This 6-in-1 device saves space, reduces upfront investment, and streamlines training for operators.

2. Improved Cutting Precision

The automatic cutting mode is a game-changer. It reduces human error, provides consistent cutting depth and width, and delivers professional-quality results that previously required separate CNC cutting systems.

3. High-Quality Welds

Laser welding is known for its speed and low distortion. With this system, weld seams are smooth, clean, and free of oxidation. Even post-processing is reduced or eliminated, saving time and labor.

4. Easy to Operate

The handheld design ensures flexibility, while the intelligent control interface allows quick switching between modes. Even less experienced operators can achieve professional results with minimal training.

5. Wide Material Compatibility

From stainless steel and carbon steel to aluminum, copper, and even dissimilar metals, this machine handles them all. It is suitable for thin sheets, medium-thickness plates, and precision components.

6. Cost Savings

Owning one multifunctional system means fewer consumables, less floor space, and lower maintenance costs compared to operating multiple separate devices.

Application Scenarios

The 6-in-1 Handheld Laser Welding Machine is designed to serve industries that demand flexibility and high precision:

- Metal Fabrication – Weld, cut, and clean components all with one tool.

- Automotive – Perfect for bodywork repair, component assembly, and precision cutting.

- Aerospace & Electronics – Achieve the tight tolerances required in high-tech industries.

- Kitchenware & Home Appliances – Produce clean seams and polished finishes with minimal post-processing.

- Construction & Maintenance – On-site adaptability with both manual and automatic cutting.

- Signage & Advertising – Cut intricate shapes and weld frames seamlessly.

Its portability also makes it a strong choice for repair workshops and field service teams.

Why Choose the 6-in-1 Over Traditional Tools?

Traditional welding and cutting tools often require separate machines, additional training, and more space. The 6-in-1 handheld laser system consolidates those functions into one easy-to-use, portable, and efficient tool. Whether you’re a large manufacturer looking to streamline operations or a smaller workshop seeking maximum flexibility, this solution delivers both performance and value.

Built for the Future

With support for up to 3000W laser power and advanced motion patterns, the system is future-proofed for demanding applications. The oscillation options—straight lines, circles, spirals, and more—allow operators to adapt welding and cutting techniques to suit different materials and joint types.

The newly added automatic cutting mode ensures you won’t need a separate machine for precision work, making this tool the ultimate all-in-one laser solution.

Conclusion

The 6-in-1 Handheld Laser Welding Machine is more than just an upgrade—it’s a revolution in multifunctional laser processing. By adding automatic cutting to the already powerful suite of welding and cleaning functions, it offers unmatched versatility, efficiency, and accuracy.

For manufacturers, workshops, and repair teams, this machine represents the perfect balance of power and flexibility. One tool, six functions, and endless possibilities.