Laser cutting is one of the most precise methods for cutting a variety of materials, including metal, plastic, and glass. However, sometimes issues can arise, resulting in poor cutting quality. One of the common problems is when the cut quality on the opposite side of the material is not up to expectations. This can lead to rough edges, incomplete cuts, or poor overall performance. In this article, we’ll explore the possible causes of one common issue and provide detailed solutions to help you achieve optimal results.

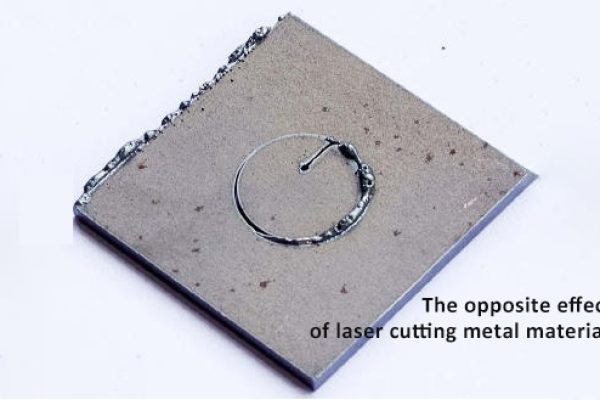

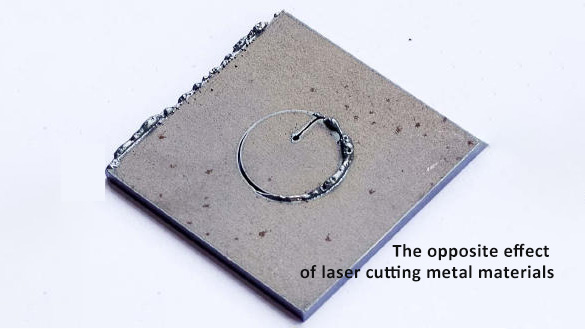

Problem: Poor Cutting on the Opposite Side of Metal Material

In the image below, you can see the problem of poor cutting results on the opposite side of the material. This is a common issue in laser cutting that can arise from several factors, ranging from the alignment of the laser beam to the condition of the laser cutting components. Let’s take a closer look at the specific causes.

Possible Causes of Poor Cutting on the Opposite Side:

- The Laser Beam Is Not in the Center

- Cause: Misalignment of the laser beam can lead to uneven cutting. The laser beam should be precisely focused at the center of the cutting area for accurate cuts. When the light is off-center, the cutting process becomes irregular, and the cut on the opposite side will be noticeably flawed.

- The Protective Lens Is Dirty

- Cause: Over time, the protective lens on the laser cutting head can accumulate dust, smoke, and other debris. This dirt can obstruct the laser beam and reduce the efficiency of the cutting process. A dirty lens results in poor laser focus and, as a result, poor cutting quality on the material.

- The Cutting Speed Is Too Fast

- Cause: Laser cutting speed plays a crucial role in determining the quality of the cut. If the cutting speed is set too high, the laser beam may not have enough time to fully penetrate the material. This can result in incomplete cuts, poor edge quality, or even burnt or rough edges on the opposite side.

- The Nozzle Is Not Round or Blocked

- Cause: The nozzle is an essential component in controlling the flow of assist gas during the cutting process. If the nozzle is not perfectly round, it can distort the gas flow, which may cause uneven cutting. Additionally, if the nozzle becomes blocked, the gas flow may be restricted, leading to poor cutting performance, including defects on the opposite side.

Solutions for Improving Cutting Quality

1. Adjust the Center of the Light

- Cause: Misalignment of the laser beam.

- Solution: The first step in addressing poor cutting results is to check the alignment of the laser beam. If the light is not centered, adjust the positioning of the laser head to ensure the beam is perfectly focused on the material. Regularly calibrating your machine to keep the laser beam aligned is crucial for consistent results. Proper alignment ensures that the laser will make clean, even cuts on both sides of the material.

2. Clean the Protective Lens or Replace It

- Cause: Dirty protective lens.

- Solution: The protective lens serves to shield the laser from debris during the cutting process. If the lens becomes dirty, it will obstruct the laser beam, leading to diminished performance and quality. To solve this, regularly clean the lens with a soft, lint-free cloth and a suitable cleaning solution. Avoid using abrasive materials that could scratch the lens. If cleaning does not restore the lens to its original condition, replace it with a new one to prevent further issues.

3. Reduce the Cutting Speed

- Cause: Cutting speed too fast.

- Solution: Cutting too quickly can prevent the laser from fully penetrating the material, resulting in incomplete cuts and poor edge quality. To fix this, slow down the cutting speed to allow the laser more time to cut through the material effectively. It’s important to find the right balance between speed and power to ensure the laser can make precise cuts. Testing different speeds for various materials will help you determine the optimal settings for the best cut quality.

4. Replace or Adjust the Nozzle

- Cause: An irregular or blocked nozzle.

- Solution: The nozzle plays a crucial role in directing the assist gas onto the material being cut. If the nozzle is deformed or blocked, the gas flow will be disrupted, leading to uneven cuts and poor cutting performance. To prevent this, inspect the nozzle regularly for signs of wear or blockages. If the nozzle is not round, replace it with a new one. If the nozzle is blocked, clean it carefully or replace it as necessary. Ensuring that the nozzle is in good condition is essential for maintaining consistent cutting quality.

Preventative Maintenance Tips for Laser Cutting Machines

In addition to the solutions mentioned above, regular maintenance is essential for preventing these problems from recurring. Here are a few tips to help you keep your laser cutting machine running smoothly:

- Regularly check and clean the protective lens: This simple step will prevent debris from accumulating and affecting cutting quality.

- Inspect and calibrate the laser alignment: Periodically check that the laser is properly aligned to avoid any misalignment issues.

- Monitor cutting speed settings: Experiment with different cutting speeds to find the optimal speed for different materials, and adjust it as necessary.

- Maintain the nozzle: Regularly inspect and clean the nozzle to ensure smooth gas flow and high-quality cuts.

Write In Final

Laser cutting is an excellent technology for precision cutting, but it requires regular maintenance and attention to detail. Poor cutting results on the opposite side of the material are often caused by misalignment, dirty lenses, fast cutting speeds, or nozzle issues. By understanding the causes of these problems and applying the appropriate solutions, you can significantly improve the quality of your cuts. Regular maintenance and calibration are also key to avoiding these issues in the future, ensuring that your laser cutting machine continues to operate at peak performance.