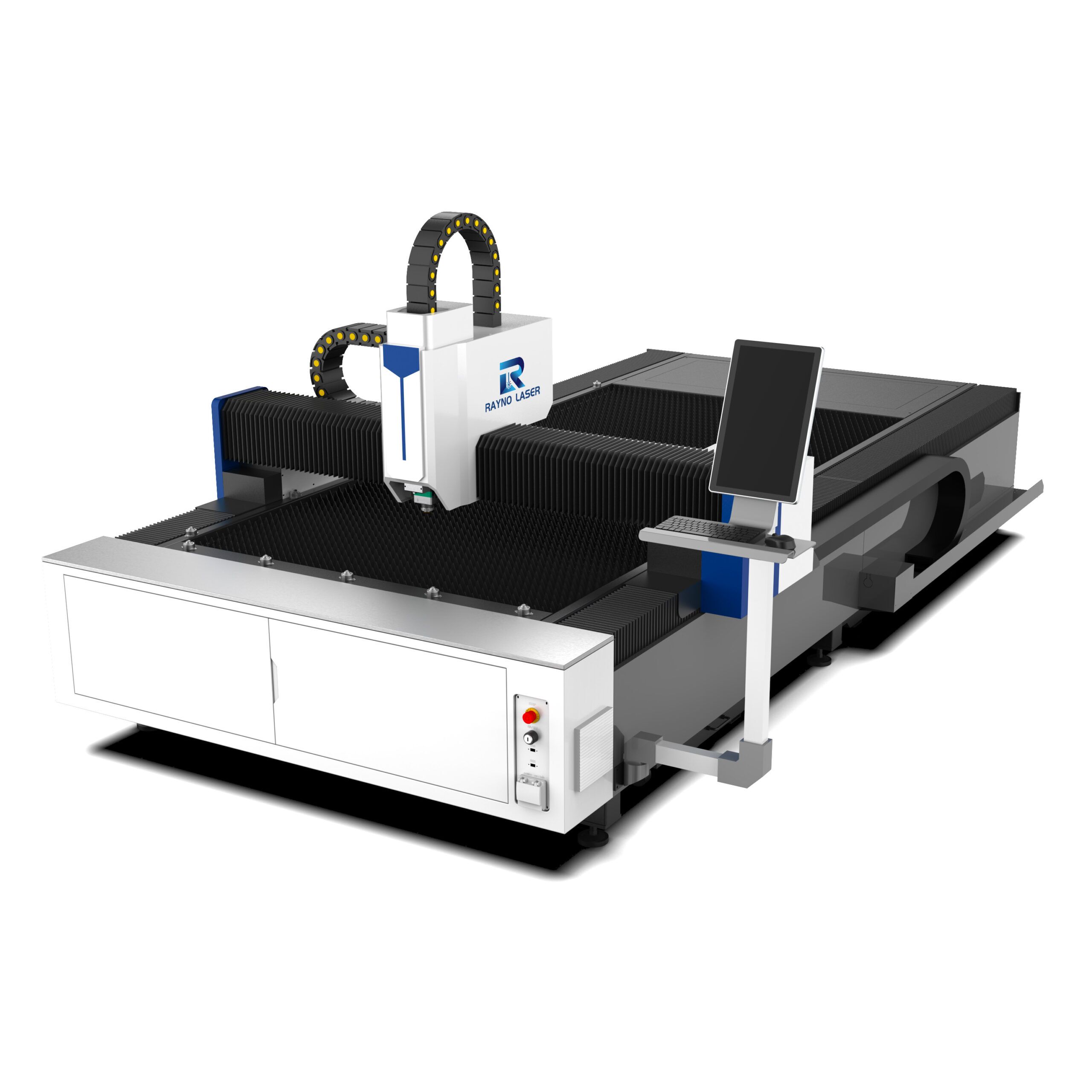

3015 Fiber Laser Cutting Machine Laser Cutter for Metal

- High Precision: Accurate cuts with minimal burrs and thermal distortion.

- Cost Efficiency: Low operating and maintenance costs with high energy efficiency.

- Fast Performance: Quick processing with maximum acceleration of 1.5G.

- Durability: Robust design with excellent heat dissipation and long-term reliability.

FOB Reference Price: Get Latest Price

PRODUCT DESCRIPTION

The RN-C3015 Fiber Laser Cutting Machine by Rayno Laser Technology is a high-performance, reliable solution designed for cutting a wide range of metals, including carbon steel, stainless steel, aluminum, brass, and more. Offering outstanding cutting precision, speed, and efficiency, this machine is ideal for industries such as automotive manufacturing, metal fabrication, aerospace, and more. With advanced features and a user-friendly design, it promises exceptional results across various applications.

Key Features and Advantages of RN-C3015 Series Fiber Laser Cutting Machine

1. High Cutting Precision

-

Beam Quality: The fiber laser cutting machine is equipped with high beam quality (BPP ≥ 3.5mm*mrad), which ensures that cuts are sharp, clean, and highly accurate. The machine delivers a smooth surface with minimal burrs, reducing the need for secondary processing.

-

Precision Engineering: The bed of the machine is fabricated using a high-precision gantry milling machine, ensuring precise positioning and long-lasting accuracy. With industrial-grade guide rails, gears, and servo control, the machine achieves repeatable positioning accuracy of ±0.02mm/m and machine tool positioning accuracy of ±0.03mm/m.

2. Exceptional Cutting Quality

-

Non-contact Cutting: The laser cutting head does not physically touch the material, preventing any damage, scratches, or deformation of the workpiece. The cutting surface is smooth, and minimal heat is applied to the material, ensuring no thermal distortion.

-

Material Versatility: Capable of cutting a variety of materials such as stainless steel, carbon steel, aluminum, brass, and more, the RN-C3015 is ideal for industries that require high versatility. Whether cutting thin or thick metal plates, this machine delivers consistent results.

3. Cost Efficiency

-

Low Operating Costs: The fiber laser’s electro-optical conversion efficiency of 40% greatly reduces electricity consumption compared to traditional laser systems. The machine is designed for long hours of operation, capable of working 24/7 with minimal maintenance costs.

-

Minimal Maintenance: The fiber laser cutting machine’s optical system uses fiber-optic transmission, which reduces maintenance requirements and enhances reliability. The simple optical path and stable structure mean less downtime and lower service costs.

4. High-Speed Performance

-

Fast Processing: The RN-C3015 boasts a maximum acceleration of 1.5G, enabling quick and efficient cuts without sacrificing accuracy. The cutting speed remains stable across various thicknesses, making it a valuable tool for high-volume production environments.

-

Efficient Workflow: The machine’s design incorporates parallel upper and lower worktables, allowing for simultaneous loading and unloading while the cutting operation takes place. This greatly enhances workflow efficiency and minimizes downtime between jobs.

Main Configuration and Technical Specifications

The RN-C3015 Series Fiber Laser Cutting Machine is designed for ease of use, with features that ensure high precision and user-friendly operation. Below are the key components and specifications that make this machine stand out:

| Component | Specification |

|---|---|

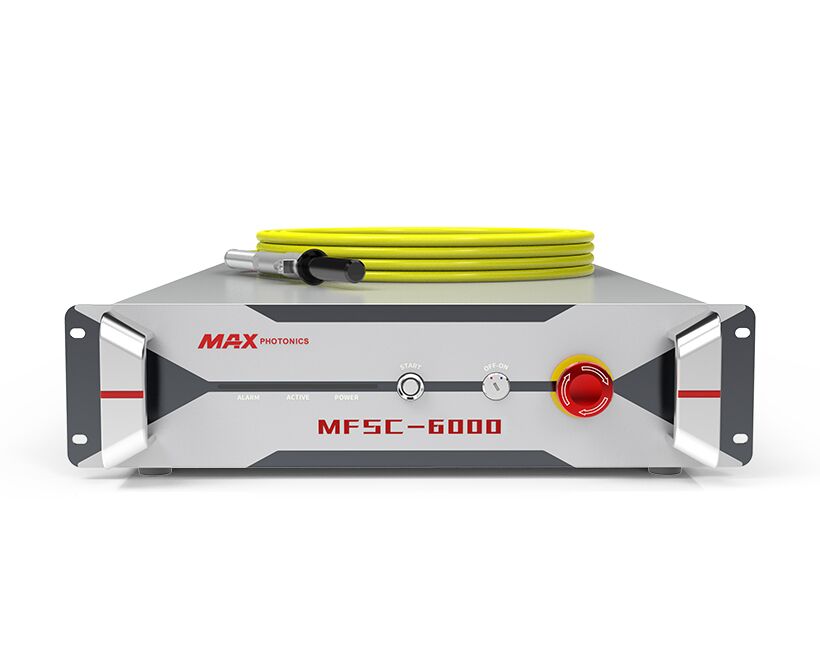

| Laser Power | 3000W/6000W (Max or Raycus) |

| Cutting Area | 3050mm x 1530mm (X-axis x Y-axis) |

| Positioning Accuracy | ±0.03mm/m |

| Repeatability Accuracy | ±0.02mm/m |

| Max Acceleration | 1.5G |

| Z-Axis Travel | 315mm |

| Machine Size | 4600mm x 2600mm x 2100mm |

| Weight | Approx. 2.4 tons |

| Power Supply | AC380V ±10%, 50Hz |

Key Components:

-

Laser Source: Max or Raycus fiber laser generator for optimal power and cutting performance.

-

Cutting Head: Equipped with a Raytools BM110 cutting head for auto-focus, ensuring precision and ease of use. And supports customized Model, such as BOCI and others.

-

Drive System: Taiwan T-WIN gear racks and linear guides ensure smooth, stable, and precise movements along the X, Y, and Z axes.

-

Control System: The CNC system is powered by FSCUT 2000E, offering intuitive operation and the ability to handle complex cutting tasks effortlessly.

Reliable and Durable Performance

The RN-C Series Fiber Laser Cutting Machine offers a robust design that ensures long-term reliability and consistent cutting quality. The bed features a strong structure with excellent heat dissipation, preventing any issues related to thermal influence. Industrial-grade components, such as the Taiwan T-WIN linear guide and high-quality servo motors, contribute to the durability and longevity of the machine.

Dust and Fume Control: The cutting process is equipped with a built-in intelligent exhaust system to effectively manage fumes and dust, maintaining a clean and safe working environment. This system ensures compliance with environmental standards and helps improve operator comfort.

Temperature Control: The dual-temperature forced water cooling system keeps the machine running at optimal temperatures, preventing overheating during long shifts. Additionally, a built-in automatic lubrication system ensures smooth operation and reduces wear and tear on mechanical parts.

Industries and Applications

The RN-C Series-3000W/6000W is ideal for cutting a wide variety of materials, making it suitable for diverse industries such as:

-

Automotive Manufacturing: Perfect for cutting metal parts used in vehicles.

-

Sheet Metal Fabrication: Ideal for producing components for machinery, enclosures, and more.

-

Aerospace: Provides precise cutting for aerospace parts.

-

Medical Equipment Manufacturing: Enables high-precision cutting of surgical equipment.

-

Construction: Used in cutting metal parts for the construction of buildings and infrastructure.

Why Choose the RN-C Series Fiber Laser Cutting Machine?

-

High Precision and Versatility: Capable of cutting a variety of materials with exceptional quality, even on intricate designs.

-

Cost-effective: High efficiency and low operating costs make it an economical choice for both small and large-scale operations.

-

Robust Design: The machine’s solid construction and efficient cooling system ensure durability and long service life.

-

User-Friendly: Easy to operate with intuitive control systems and minimal maintenance requirements.

With its outstanding features, reliable performance, and cost efficiency, the RN-C Series Fiber Laser Cutting Machine is an excellent choice for industries that require high-precision, high-speed, and versatile cutting solutions.

TECHNICAL PARAMETERS

Additional information

| Machine working area | 1500×3000mm |

|---|---|

| Resetting positioning accuracy | ±0.02mm |

| Working speed | 100m/min |

| X/Y Axis Position Accuracy | ±0.03mm/1000mm |

| Max Acceleration | 1.5G |

VIDEO

SAMPLE DISPALY

Send your messages to the supplier

Get additional product information or technical support. Our team is always available to provide you with the necessary guidance and solutions.