Applications

As industries demand higher efficiency and deeper cleaning performance, laser cleaning technology has become a proven alternative to traditional surface treatment methods such as sandblasting and chemical cleaning. While 3kW continuous-wave (CW) laser cleaning machines are widely used for general applications, many heavy-duty industries now require higher power, faster processing speed, and stronger removal capability.

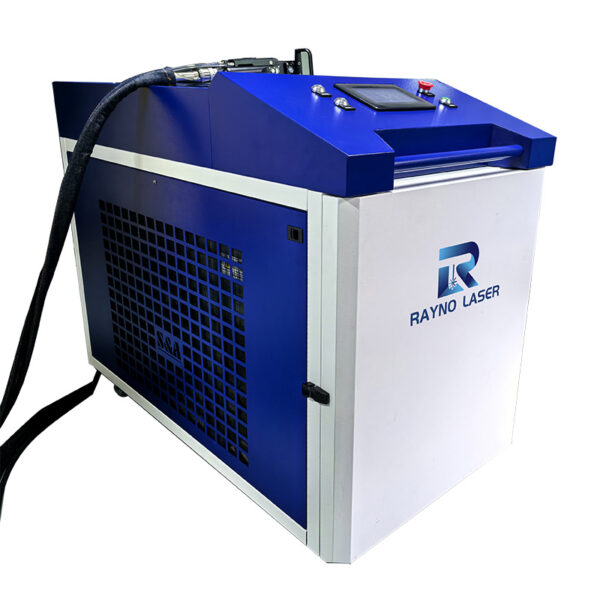

To meet these requirements, Rayno Laser has developed a 6000W continuous laser cleaning machine, offering significantly enhanced performance. Today, this system is already widely applied in ship cabin manufacturing, ship maintenance, and marine engineering, with multiple customer application videos validating its effectiveness in real production environments.

🔧 Why Power Matters in Laser Cleaning

In continuous laser cleaning, laser power directly affects cleaning depth, speed, and efficiency. Compared with pulsed systems, CW laser cleaners are particularly suitable for:

- Thick rust and oxide removal

- Large-area paint stripping

- Weld seam cleaning

- Heavy-duty industrial surface preparation

However, as material thickness and contamination severity increase, standard 3000W CW systems can reach their performance limits. This is where the Rayno 6000W laser cleaning machine demonstrates its advantages.

⚡ 6000W vs 3000W: A Clear Performance Difference

Compared to a typical 3kW continuous laser cleaning machine, the Rayno 6000W system delivers:

✔ Stronger Cleaning Capability

With double the output power, the 6000W laser provides higher energy density, allowing faster removal of thick rust layers, marine coatings, and stubborn contaminants commonly found in ship cabins and steel structures.

✔ Higher Processing Speed

In practical applications, the 6000W system can achieve up to 30–50% higher cleaning efficiency, significantly reducing operation time on large metal surfaces.

✔ Better Suitability for Heavy Steel Structures

Shipbuilding and marine maintenance involve carbon steel plates, welded joints, and confined cabin spaces. The 6000W laser offers stable, continuous output for long-duration cleaning tasks without performance degradation.

🚢 Proven Applications in Ship Cabin Manufacturing and Maintenance

The Rayno Laser 6000W continuous laser cleaning machine is now extensively used in:

- Ship cabin manufacturing – removal of mill scale and rust before welding or coating

- Ship maintenance and repair – cleaning corroded steel surfaces inside cabins

- Marine steel structures – paint stripping and surface preparation

- Weld seam pre- and post-treatment – oxide and residue removal

Unlike abrasive blasting, laser cleaning generates no secondary waste, making it especially suitable for enclosed ship cabins where dust control and environmental safety are critical.

Rayno Laser has accumulated real customer application videos from shipyards and marine maintenance companies, demonstrating stable operation, high efficiency, and consistent cleaning quality under real working conditions.

Machine Quick Link

6KW fiber laser cleaning machine

The 6kW Laser Cleaning Machine is powered by a MAX 6000W continuous fiber laser and features a high-performance cleaning head for superior precision and efficiency. Its S&A cooling system ensures stable operation, while adjustable cleaning widths (200–500mm) boost productivity. With real-time monitoring, smartphone connectivity, and durable water-cooled design, it’s perfect for industrial rust, paint, and mill scale removal.

⚙️ Technical Overview: Rayno 6000W CW Laser Cleaning Machine

Key Technical Features:

- Laser Type: Continuous-wave fiber laser

- Output Power: 6000W

- Cleaning Mode: Non-contact, linear scanning

- Materials: Carbon steel, stainless steel, marine-grade alloys

- Operation Options: Handheld or robotic integration

- Cooling System: Industrial water cooling for long-term stability

The system is engineered for continuous industrial operation, ensuring reliable performance during extended cleaning tasks typical in shipyards.

🌱 A Safer and More Sustainable Alternative

Traditional ship maintenance methods such as sandblasting pose several challenges:

- Dust and abrasive contamination

- High labor intensity

- Complex waste disposal

- Safety risks in confined spaces

By contrast, the Rayno 6000W laser cleaning system offers:

- No consumables

- No chemical waste

- Minimal noise and vibration

- Improved operator safety

These benefits make laser cleaning increasingly favored in marine and offshore industries, where environmental compliance is becoming stricter.

📈 Designed for High-Demand Industries

The Rayno 6000W continuous laser cleaner is ideal for industries that require:

- High cleaning speed

- Deep rust and coating removal

- Large-area surface preparation

- Stable performance in harsh environments

Typical application sectors include:

- Shipbuilding and ship repair

- Marine engineering

- Heavy machinery manufacturing

- Steel structure fabrication

- Energy and offshore equipment

🎥 Real Customer Application Videos

To help customers better understand real-world performance, Rayno Laser provides actual customer application videos showcasing:

- Cleaning efficiency on thick marine rust

- Operation inside ship cabins

- Large steel surface treatment

- Continuous operation in industrial environments

These videos demonstrate how the 6000W system performs beyond laboratory conditions — directly on production sites.

🚀 Conclusion: When 3000W Is Not Enough

While 3kW continuous laser cleaning machines are suitable for light to medium applications, heavy-duty industries demand more power and efficiency.

The Rayno Laser 6000W continuous laser cleaning machine delivers the performance required for shipbuilding, ship maintenance, and other high-demand industrial environments.

With proven field applications, strong cleaning capability, and reliable operation, Rayno’s 6000W system is a powerful solution for customers who require industrial-grade laser cleaning performance.

📩 Contact Rayno Laser

If your application requires high-power laser cleaning, contact Rayno Laser today for technical consultation, system configuration, or to view our latest customer application videos.

Email: sales@raynolaser.com

Website: www.raynolaser.com