Compact MINI Laser Cutting Head for Small Platforms and Desktop Systems

Compared with conventional cutting heads designed for large industrial machines, this compact model offers clear benefits:

- Smaller size, better suited for limited installation space

- Lower cost for small-area and precision cutting

- Reduced system load on lightweight machines

- Easier integration with desktop and small-format platforms

- Optimized for craft, small parts, and customized production

FOB Reference Price: Get Latest Price

PRODUCT DESCRIPTION

Designed for Precision Cutting on Small-Scale Applications

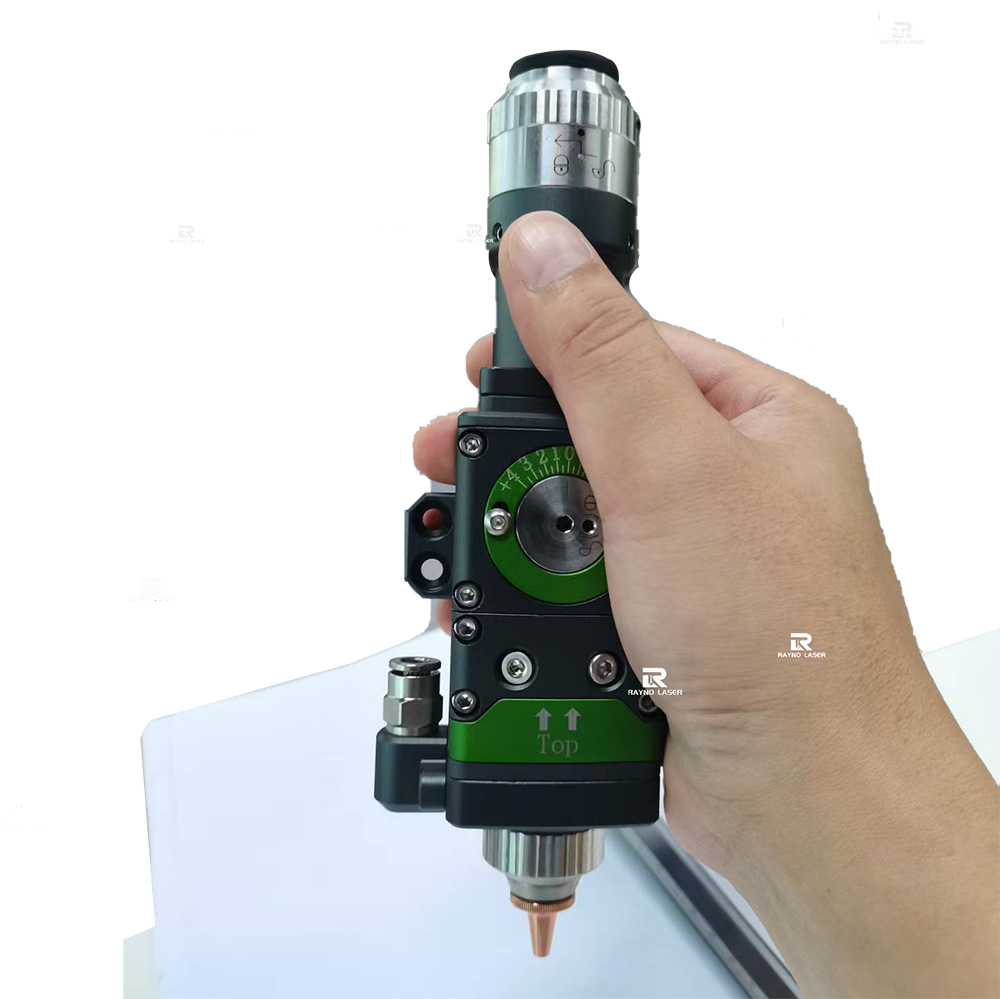

As laser cutting technology continues to expand beyond large industrial systems, there is a growing demand for compact, efficient, and cost-effective cutting solutions. Rayno Laser introduces a compact laser cutting head specifically designed for small platforms, desktop laser cutting machines, and precision cutting of small-format materials.

Compared with conventional cutting heads used on large-format machines, this model features a smaller footprint, lighter structure, and lower operating cost, making it ideal for users who focus on fine-detail processing rather than large-scale production.

Compact Design for Small Cutting Platforms

One of the most significant advantages of this cutting head is its compact mechanical structure. Unlike traditional cutting heads that require large installation space and rigid machine frames, this model is optimized for small worktables and limited installation environments.

Its reduced size and weight allow:

-

Easier integration with desktop laser cutting machines

-

Improved motion response on lightweight gantry systems

-

Stable operation on small-format cutting platforms

-

Lower requirements for machine rigidity and load capacity

This makes it especially suitable for compact laser systems where space efficiency and mechanical balance are critical.

Cost-Effective Solution for Small-Area Cutting

For users cutting small materials or limited working areas, using a conventional industrial cutting head often leads to unnecessary cost and complexity. Rayno Laser’s compact cutting head offers a more economical alternative, reducing both initial investment and long-term operating expenses.

Key cost advantages include:

-

Lower overall system cost

-

Reduced maintenance and consumable expenses

-

Simplified structure with fewer high-cost components

-

Efficient performance without over-specification

This allows users to achieve reliable cutting performance while keeping total ownership cost under control.

Ideal for Craft, Hobby, and Small Product Manufacturing

This cutting head is particularly well suited for applications where precision, flexibility, and small-batch production are required. Typical use cases include:

-

Craft and decorative metal cutting

-

Small product components and accessories

-

Customized parts and creative designs

-

Thin metal sheets and non-ferrous materials

-

Educational, R&D, and prototyping environments

For manufacturers and creators working with small-sized materials, this cutting head delivers clean edges and stable cutting results without the need for large industrial equipment.

Optimized Optical Structure for Stable Performance

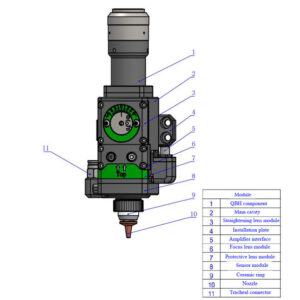

Despite its compact size, the cutting head adopts a reliable optical configuration that ensures stable beam transmission and consistent cutting quality. The internal optical layout is designed to maintain good energy concentration, helping achieve smooth kerf edges and reducing thermal impact on surrounding material.

The protective lens structure effectively shields internal optics from dust and spatter, supporting long-term stability and reducing the frequency of optical maintenance.

Efficient Gas Flow and Nozzle Compatibility

A well-designed internal gas channel ensures uniform assist gas delivery to the cutting zone. This improves molten material removal and contributes to cleaner cut edges, even when processing small parts with fine details.

The cutting head supports commonly used nozzle types, allowing users to select appropriate nozzles based on material type and thickness. This flexibility enhances cutting adaptability across different small-scale applications.

Easy Integration and Maintenance

Designed with simplicity in mind, this cutting head is easy to install, adjust, and maintain. The modular structure allows quick access to key components such as protective lenses and nozzles, minimizing downtime during routine maintenance.

Its lightweight design also reduces wear on motion systems, further improving overall system reliability on compact machines.

Typical Applications

This compact laser cutting head is especially suitable for:

-

Desktop laser cutting machines

-

Small-format laser cutting systems

-

Craft and decorative metal processing

-

Small product manufacturing and customization

-

Educational and prototyping platforms

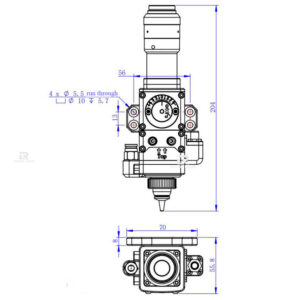

Main Specifications Overview

| Product Parameters | |

| Optical fiber interface | QBH |

| Wavelength range | 1070±20nm |

| Rated power | ≦2000W |

| Collimation focal length | 50mm |

| Focusing length | 75mm |

| Focus adjustment range | ±9mm |

| Auxiliary gas pressure | ≤25Bar |

| Effective light aperture | 15mm |

| Weight | 0.785KG |

Note: Specifications may vary depending on configuration and application requirements.

Competitive Advantages Compared to Standard Cutting Heads

Compared with conventional cutting heads designed for large industrial machines, this compact model offers clear benefits:

-

Smaller size, better suited for limited installation space

-

Lower cost for small-area and precision cutting

-

Reduced system load on lightweight machines

-

Easier integration with desktop and small-format platforms

-

Optimized for craft, small parts, and customized production

These advantages make it an ideal choice for users who prioritize precision, flexibility, and cost efficiency over large-scale production capacity.

This mini compact laser cutting head is purpose-built for small platforms and desktop laser cutting systems. By combining a space-saving design, stable optical performance, and cost-effective operation, it provides a practical solution for cutting small materials with precision and reliability.

For craft makers, small manufacturers, and system integrators seeking a compact, efficient, and affordable cutting head, this product delivers the right balance between performance and practicality.

TECHNICAL PARAMETERS

Additional information

| Cutting Mode | 2D |

|---|---|

| Focusing Length | F75mm |

| Accuracy | 0.01mm |

| Nozzle specifications | single layer |

| Fiber Interface | QBH |

| Weight | 0.8kg |

VIDEO

SAMPLE DISPALY

Send your messages to the supplier

Get additional product information or technical support. Our team is always available to provide you with the necessary guidance and solutions.