In the realm of modern manufacturing, precision, efficiency, and versatility are paramount. This is where handheld laser welding machines emerge as game-changers, offering a revolutionary approach to welding that combines precision with portability. Let’s delve into what handheld laser welding machines are and why they are becoming indispensable tools in various industries.

What is a Handheld Laser Welding Machine?

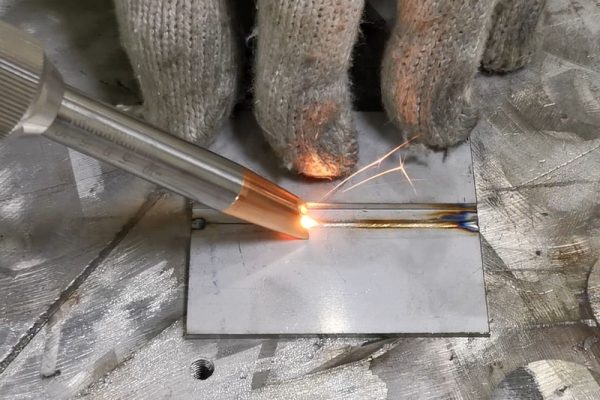

A handheld laser welding machine is a cutting-edge tool designed to facilitate precise and efficient welding operations. Unlike traditional welding methods that rely on welding torches or electrodes, handheld laser welding machines harness the power of laser technology to join materials together. These machines are compact, portable, and offer exceptional control, making them ideal for a wide range of applications.

How Does It Work?

At the heart of a handheld laser welding machine is a high-powered laser beam. This laser beam is focused and directed onto the workpiece, creating a localized area of intense heat. As the laser beam interacts with the material, it melts and fuses the surfaces together, forming a strong and durable weld. The precise control of the laser beam allows for fine adjustments, enabling operators to achieve intricate welds with minimal distortion.

Key Features and Advantages:

- Precision Welding: Handheld laser welding machines offer unparalleled precision in welding operations. The focused laser beam ensures that heat is applied precisely where it is needed, resulting in clean and precise welds.

- Portability: Being handheld, these machines offer remarkable portability. Operators can easily maneuver the machine to reach tight spaces or move it from one workpiece to another, making them ideal for on-site or field applications.

- Versatility: Handheld laser welding machines can weld a wide range of materials, including stainless steel, aluminum, copper, and more. This versatility makes them suitable for industries such as automotive, aerospace, electronics, and jewelry.

- Efficiency: Laser welding is a fast and efficient process. The concentrated heat source of the laser beam allows for quick melting and solidification of the material, leading to shorter processing times and increased productivity.

- Reduced Heat Affected Zone (HAZ): Laser welding produces a narrow and focused heat-affected zone, minimizing the risk of distortion or damage to the surrounding material. This is particularly beneficial when working with delicate or heat-sensitive materials.

- Clean and Neat Welds: The precise control of the laser beam results in clean and smooth welds, reducing the need for extensive post-welding cleanup.

- Cost-effectiveness: While handheld laser welding machines represent a significant initial investment, they can offer long-term cost savings. Their efficiency, precision, and versatility can lead to reduced material waste and labor costs over time.

Applications:

Handheld laser welding machines find applications across various industries, including:

- Automotive: Welding of automotive components, body panels, and exhaust systems.

- Aerospace: Joining of aircraft components, such as fuselage sections and engine parts.

- Electronics: Welding of electronic components, circuit boards, and battery packs.

- Manufacturing: Welding of metal parts, fabrication of prototypes, and production of small-scale components.

Conclusion

In conclusion, handheld laser welding machines are revolutionizing the field of precision joining. Their combination of precision, portability, versatility, and efficiency makes them indispensable tools in modern manufacturing. As industries continue to demand higher quality and faster production times, handheld laser welding machines are poised to play an increasingly vital role in meeting these demands.

Whether it’s joining critical aerospace components, or fabricating automotive parts, handheld laser welding machines offer a cutting-edge solution that is reshaping the way we weld. As technology continues to advance, we can expect to see even greater innovations in this field, driving efficiency, productivity, and quality to new heights.

One Response

555