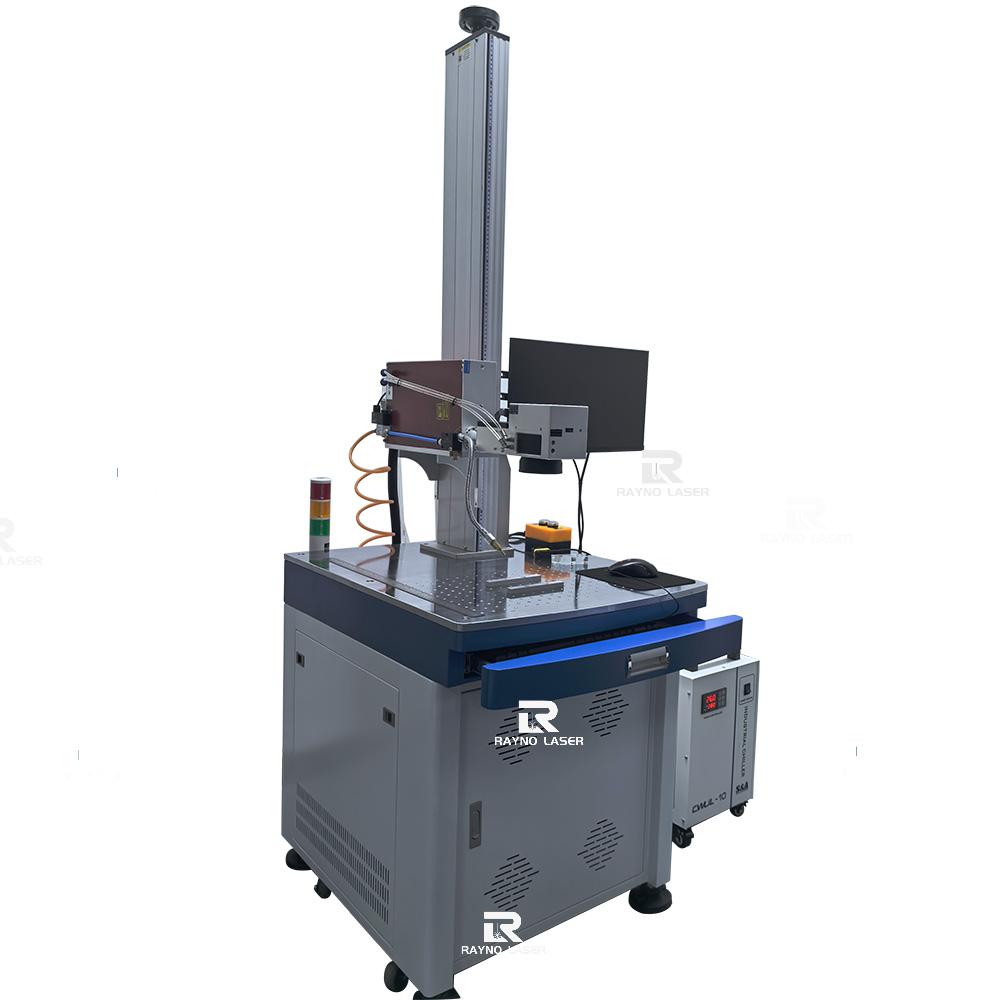

As industries continue to demand greater accuracy, faster turnaround times, and cost-effective manufacturing solutions, the Laser Glass Drilling Machine has become an essential tool for processing glass components. At Rayno Laser, we are glad to introduce our newly compact glass drilling machine, specifically engineered for businesses that require high precision for small products without the complexity, space requirements, and expense of large industrial systems.

This innovative solution combines professional-grade performance with user-friendly operation, making laser glass drilling more accessible than ever.

Why Choose a Compact Laser Glass Drilling Machine?

Traditional large laser machining centers are powerful but often come with limitations for small and medium manufacturers, including high investment costs, large installation space, complicated operation procedures, and higher maintenance requirements.

Rayno’s compact laser glass drilling machine directly addresses these pain points:

- Small footprint: Designed to fit easily into limited workshop spaces.

- Easy operation and maintenance: Streamlined software control and simplified mechanical structure reduce training time and maintenance workload.

- Affordable pricing: Offers a significantly lower cost compared to large-scale laser equipment, allowing faster return on investment.

- Professional-grade results: Delivers drilling accuracy and processing performance comparable to larger systems.

This makes the compact machine an ideal choice for manufacturers who frequently handle small glass parts, customized products, prototyping, or batch production where precision and efficiency are critical.

High-Precision Laser Drilling for Multi-Glass Materials

Despite its compact size, this laser glass drilling machine is designed to process a wide range of glass materials, including:

- Cover glass

- Optical glass

- Borosilicate glass

- Decorative and architectural glass

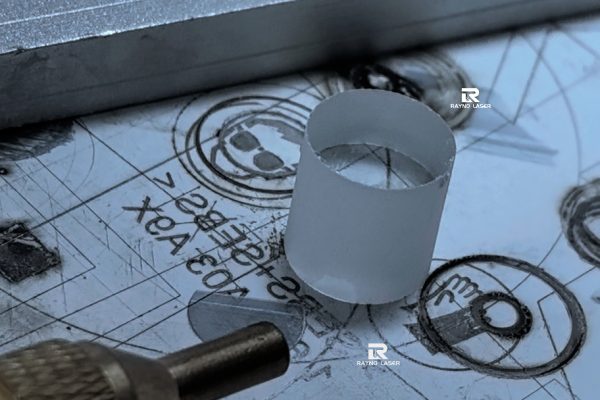

The machine supports drilling glass thicknesses up to 25 mm, offering excellent versatility across different application sectors. Precision laser processing ensures:

- Clean, round holes with minimal chipping

- High repeatability

- Stable drilling quality across various thicknesses

- Very low thermal impact compared to mechanical drilling

The contact-free nature of laser drilling completely eliminates tool wear, vibration, and mechanical stress on glass, ensuring long-term production stability and consistent quality.

Multi-Function Laser System: More Than Just Glass Drilling

One of the major advantages of this new system is its multi-purpose functionality, allowing users to unlock more production value from a single machine.

Core Processing Functions:

- Laser Glass Drilling

- High-precision hole drilling for small components

- Consistent edge quality

- Suitable for thin to thick glass up to 25 mm

- Deep Laser Engraving on Glass

- Capable of producing deep artistic engraving or textured patterns

- Suitable for logos, decorative effects, personalization, and industrial identification

- Metal Marking

- Supports laser engraving and marking on various metals including stainless steel, aluminum, brass, and coated metals

- Ideal for serial numbers, barcodes, QR codes, logos, and traceability marks

This “one machine, multiple applications” capability significantly reduces the need for multiple pieces of equipment, saving both investment costs and floor space while improving overall production flexibility.

Ideal Applications

Thanks to its precision, versatility, and compact design, the Rayno compact laser glass drilling machine is widely used across numerous industries:

- Consumer electronics – camera holes, sensor openings, speaker perforations, decorative glass panels

- Smart home products – display covers, control panel glass

- Optical components – lenses, filters, laboratory glassware

- Decorative glass products – artistic engravings, personalized gifts

- Automotive glass parts – marking or drilling small glass components

- Metal accessories and components – permanent serial marking and branding

Whether you produce customized samples, OEM parts, or short-to-medium production runs, this compact laser system enables efficient, flexible, and precise manufacturing.

Compact vs. Large Laser Drilling Machines

| Feature | Compact Laser Glass Drilling Machine | Large Laser Drilling Systems |

|---|---|---|

| Footprint Size | Small, space-saving | Large, requires dedicated installation area |

| Ease of Operation | Simple setup and user-friendly software | Complex operation, extensive training required |

| Maintenance | Lower maintenance, easy service access | Higher maintenance complexity and cost |

| Initial Investment | Affordable | High capital investment |

| Best Use | Small parts, customized production, flexible workshops | High-volume, large-format processing |

| Multi-Function Use | Glass drilling, deep engraving, metal marking | Usually single or limited application focus |

This comparison highlights how Rayno’s compact solution delivers outstanding value for manufacturers seeking agility and cost-efficiency without sacrificing drilling performance.

Focused Benefits at a Glance

When searching for a laser glass drilling machine, potential customers are looking for:

- High drilling accuracy

- Fast processing speed

- Low machine cost

- Easy operation

- Versatility for multiple applications

Rayno’s compact laser glass drilling machine meets all these expectations by providing:

- Precision drilling up to 25 mm thick glass

- Compact industrial design for space optimization

- Affordable entry-level professional laser system

- Multi-function laser processing for diverse materials

Conclusion

The new Rayno Compact Laser Glass Drilling Machine represents the perfect balance between performance, affordability, and usability. It delivers reliable laser glass drilling accuracy at a cost and size that fit modern workshops and small production environments. With added capabilities for deep glass engraving and metal marking, it is truly a multi-purpose laser processing solution designed to grow alongside your business.

If you are seeking a professional yet cost-effective laser glass drilling machine for small products or flexible production needs, Rayno’s latest model is the ideal choice for maximizing efficiency and return on investment.