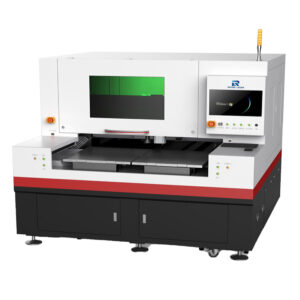

In the rapidly evolving glass processing industry, manufacturers face increasing challenges in meeting the growing demand for high-precision, efficient, and eco-friendly solutions. Traditional CNC methods, while long-established, are no longer sufficient for addressing these modern demands. That’s where our new laser glass cutting machine series steps in, offering two cutting-edge models tailored for the diverse needs of the industry.

What Makes Our Laser Glass Cutting Machine Different?

Unlike traditional CNC systems, which rely on mechanical cutting tools and cutting fluids, our laser glass cutting machines leverage advanced infrared picosecond laser technology to deliver unparalleled precision and efficiency. Here’s what sets our machines apart:

- Two Models for Versatility:

- Cutting-Only Model: Ideal for manufacturers focusing solely on high-precision glass cutting.

- Cutting + Splitting Model: Combines infrared picosecond cutting lasers with a 10.6μm laser splitting system for added functionality.

- Customizable Power Options:

Choose from 30W, 50W, 60W, or 80W infrared picosecond lasers, tailored for cutting glass of various thicknesses with high precision. - High Cutting Strength and Minimal Chipping:

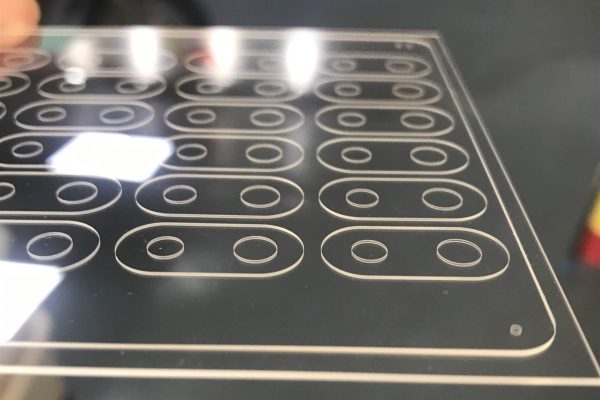

Achieve smooth, clean edges with minimal chipping and exceptional cutting strength, even for brittle materials like ultra-clear glass, quartz glass, and borosilicate glass. - Eco-Friendly Operation:

Eliminates the need for cutting fluids, addressing the growing concerns about environmental pollution. - Compact and Efficient Design:

Reduces the need for large spaces and extensive manpower, offering a cost-effective and scalable solution for manufacturers.

What Industry Challenges Does This Machine Solve?

- How to Cut Glass with Precision and Speed?

Traditional CNC systems often result in inconsistent cutting edges, tool wear, and slower processing speeds. Our machine solves this with infrared picosecond lasers, delivering:- Taper-free cuts

- Precision at the micrometer level

- Cutting speeds of up to 500mm/s, significantly boosting production efficiency.

- How to Handle Brittle Materials Without Breakage?

Materials like smartphone glass covers, LCD screens, and high borosilicate glass are prone to cracking during processing. Our laser system ensures:- Non-contact cutting, reducing stress on materials.

- Smooth, consistent results, ideal for high-demand industries like consumer electronics and automotive manufacturing.

- How to Reduce Production Costs and Environmental Impact?

CNC systems require frequent tool replacements, cutting fluids, and extensive labor, leading to high operational costs. Our laser cutting machine:- Eliminates tool wear, reducing maintenance expenses.

- Operates without cutting fluids, making it eco-friendly.

- Requires minimal manpower, saving both labor and space costs.

Who Can Benefit from This Machine?

Our laser glass cutting machines are designed to cater to a wide range of applications and industries:

- Consumer Electronics:

- Cutting and splitting of smartphone glass covers, camera glass, and LCD screens with precision and minimal chipping.

- Automotive Industry:

- Processing car glass for displays and camera modules with high strength and clarity.

- Optics and Photonics:

- Precision cutting of materials like quartz glass, K9 glass, and optical filters for high-end optical devices.

- Specialty Applications:

- Splitting and cutting mirrors, plain white polymer glass, and ultra-clear glass for various industrial uses.

Why Should You Choose This Glass Cutting Machine?

- Enhanced Productivity:

Our machine’s dual-platform models ensure uninterrupted operation. While one platform processes the material, the other can be loaded or unloaded, increasing efficiency. - Future-Proof Technology:

Infrared picosecond lasers represent the latest advancement in glass processing, ensuring that you stay ahead of industry trends. - Precision Without Compromise:

With cutting-edge CCD vision positioning systems and a focus spot of <2μm, our machine delivers consistent results every time. - Reduced Maintenance:

Say goodbye to frequent tool replacements and machine downtime. Our laser system is designed for durability and reliability.

Glass Cutting Machine on Sale.

The glass processing industry is at a turning point, and our laser glass cutting machine series provides the perfect solution to meet modern demands for efficiency, precision, and sustainability. Whether you’re cutting ultra-clear glass for smartphones, splitting quartz for optical filters, or processing automotive glass, our machines offer the versatility and performance to revolutionize your production line.

Don’t let outdated CNC methods hold you back. Upgrade to the future of glass cutting and splitting with our laser technology!

👉 Contact us today to learn more or schedule a demonstration!

2 Responses

To be more modest it is necessary

You’ve taken something complex and made it feel like a peaceful walk through familiar terrain.