A Smarter Way to Manage Your Laser Equipment

If you use laser welding or laser cleaning in your business, you’ve probably faced challenges like:

- Struggling to find the right welding or cleaning settings

- Machine downtime with no quick way to fix it

- Complicated software that’s difficult to adjust

- Slow or expensive after-sales support

At Rayno Laser, we understand these frustrations. That’s why we developed the V4 Laser Control System—a smarter, faster, and easier way to manage your laser machines. Whether you’re adjusting parameters, troubleshooting issues, or updating software, V4 simplifies every step so you can spend more time working and less time fixing problems.

Why Do You Need the V4 Control System?

1. No More Guesswork—Get the Right Settings Instantly

Laser welding and cleaning require precise settings, but manually adjusting parameters can be time-consuming and frustrating—especially when working with different materials.

With V4, you get a pre-set database that lets you quickly choose the best settings for your specific job. Whether you’re welding stainless steel, aluminum, or carbon steel, the system provides optimized parameters, so you don’t waste time experimenting.

Key Benefits:

- No need for manual testing—just select the right material and thickness

- Works for various metals and surface conditions

- Quickly switch between welding and cleaning modes

For beginners, this means fewer mistakes. For experienced operators, it means higher efficiency and better consistency.

2. Control Your Machine from Anywhere—Right from Your Phone

Have you ever wished you could adjust your laser settings without standing next to the machine? Now you can!

With V4’s mobile app, you can:

✅ Adjust welding or cleaning parameters remotely

✅ Monitor your machine’s performance in real time

✅ Quickly switch between different jobs

This feature is especially useful for large workshops where operators move between different tasks. It also improves safety, as users can control the machine without direct exposure to the laser.

3. Fix Issues Without Waiting for a Technician

One of the biggest headaches for laser equipment users is downtime. When your machine stops working, you lose time, money, and production efficiency.

V4 helps eliminate these delays with cloud-based remote diagnostics. Instead of waiting for a technician to visit, suppliers can remotely check your machine’s status and troubleshoot problems.

What this means for you:

- Faster problem-solving—no need to wait for on-site service

- Lower maintenance costs—get help remotely instead of paying for technician visits

- Automatic software and firmware updates—no manual installations required

And if you prefer solving issues yourself, the V4 system includes step-by-step troubleshooting guides and tutorial videos, allowing you to fix common problems in minutes.

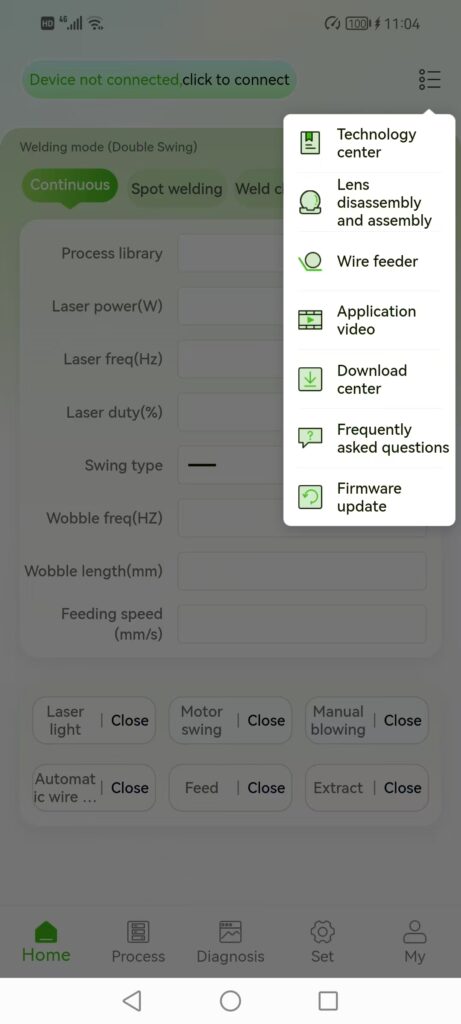

More Features That Make Your Work Easier

- Multi-Language Support – The system is available in English, Russian, and Chinese, making it accessible to a global user base.

- Technology Center – A built-in knowledge hub with detailed guides on laser operation, troubleshooting, and optimization.

- Lens Maintenance Guides – Step-by-step instructions for removing, cleaning, and assembling lenses, so you avoid costly mistakes and extend the life of your optics.

- Wire Feeder– Teach you how to install and use the wire feeder step by step

- Application Video Library – Watch quick, practical tutorials on setting up, using, and maintaining your laser machine.

- Download Center – Easily access software updates, user manuals, and troubleshooting documents without needing technical support.

- Firmware Updates – The V4 system keeps your machine up to date automatically, eliminating the hassle of manual installations.

How Does V4 Compare to Older Control Systems?

| Feature | Older Control Systems | V4 Control System |

|---|---|---|

| Parameter Adjustment | Manual input, trial and error | Pre-set database, one-click selection |

| Remote Control | Not available | Full control via mobile app |

| Troubleshooting | Requires technician visit | Remote diagnostics & guided troubleshooting |

| Language Options | Limited to one language | Supports English, Russian, and Chinese |

| Software Updates | Manual downloads & installations | Automatic cloud-based updates |

| Training & Support | Requires external training | Built-in technology center & video library |

With V4, you get a faster, easier, and more efficient way to control your laser welding and cleaning machines.

Who Can Benefit from the V4 Control System?

The V4 Laser Control System is designed for a wide range of industries and applications, including:

✔ Manufacturers – Improve efficiency and reduce machine downtime in your production lines.

✔ Small Businesses – Get an easy-to-use, low-maintenance laser system that saves time and resources.

✔ Metal Fabrication Shops – Quickly adjust welding and cleaning settings for different materials and jobs.

✔ Automotive & Aerospace Industries – Ensure precision and consistency in high-quality welding applications.

✔ Operators of All Skill Levels – Whether you’re a beginner or an expert, V4 makes your work easier and more efficient.

Real-World Benefits of Upgrading to V4

Still wondering whether the V4 system is worth it? Here’s how it can transform your laser welding and cleaning operations:

🔹 Reduce Setup Time by 50% – Thanks to the pre-set database, you can start welding or cleaning faster with optimal settings already configured.

🔹 Minimize Downtime – Remote diagnostics and troubleshooting mean less waiting for technical support and more time keeping your business running.

🔹 Improve Product Quality – With precise control and an easy-to-use interface, you can achieve more consistent, higher-quality welds and cleaning results.

🔹 Lower Maintenance Costs – Automatic firmware updates and step-by-step maintenance guides help prevent costly repairs and extend the life of your equipment.

🔹 Enhance Operator Safety – Mobile app control allows operators to adjust settings and monitor performance from a safe distance.

Why Choose V4 Over Other Laser Control Systems?

At Rayno Laser, we designed V4 to address the most common frustrations faced by laser welding and cleaning professionals. Unlike traditional control systems that require constant manual adjustments, expensive technician visits, and outdated software, V4 provides a smart, connected, and user-friendly solution.

By choosing V4, you’re investing in:

✅ Efficiency – Work smarter with easy-to-use settings and remote control.

✅ Reliability – Reduce machine downtime and fix issues faster.

✅ Innovation – Stay ahead with cutting-edge cloud-based support and updates.

Machines that support V4 system.

-

6KW fiber laser cleaning machine

6KW fiber laser cleaning machine -

Pulsed Fiber Laser Cleaning Machine for Paint Remove

Pulsed Fiber Laser Cleaning Machine for Paint Remove -

Ralfar Double Motor Wobbling Handheld Laser Cleaning Head

Ralfar Double Motor Wobbling Handheld Laser Cleaning Head -

Ralfar Intelligent Wobbling Handheld Laser Cleaning Head

Ralfar Intelligent Wobbling Handheld Laser Cleaning Head -

Ralfar Intelligent Handheld Laser Cleaning Head

Ralfar Intelligent Handheld Laser Cleaning Head -

China 5 in 1 handheld laser welding machine with distributor price

China 5 in 1 handheld laser welding machine with distributor price -

5 in 1 Laser Head for Handheld laser welding machine wobble laser gun

5 in 1 Laser Head for Handheld laser welding machine wobble laser gun -

4 in 1 Laser Gun Laser Head for Welding Cutting and Cleaning

4 in 1 Laser Gun Laser Head for Welding Cutting and Cleaning

Upgrade to V4 and Transform Your Laser Operations Today

The V4 Laser Control System is more than just a software update—it’s a complete upgrade for your laser welding and cleaning workflow.

With smarter settings, remote access, and real-time troubleshooting, V4 saves you time, reduces costs, and improves your overall productivity.

🔹 Simpler operation

🔹 Faster troubleshooting

🔹 Less downtime, more efficiency

Want to see it in action? Contact us today for a demo or consultation and experience the difference V4 can make for your business!