In today’s fast-paced glass fabrication industry, manufacturers face a common challenge: how to deliver multiple types of high-precision glass processing—like drilling, marking, and sandblasting—without slowing down production or risking breakage. Traditional tools are often bulky, slow, or limited in functionality. The solution? A laser glass cutter that can do it all.

Meet the Rayno Laser Glass Drilling Machine—a smart, multi-functional solution designed to handle glass drilling, paint removal, laser marking, and sandblasting effects all in one system. If you’re in the architectural glass, smart mirror, or decorative glass industry, this is the all-in-one machine that can transform your workshop into a high-efficiency production hub.

Why Choose a Laser Glass Drilling Machine?

Unlike conventional equipment, laser systems offer non-contact, high-precision processing with minimal risk of cracks or chips. Whether you’re looking to cut holes in glass, engrave logos, or remove coatings, the Rayno machine provides unmatched reliability and finish quality.

Here’s how it solves the common pain points glass manufacturers face:

✅ Multi-Functionality for Maximum Output

One of the most compelling advantages of the Rayno machine is its all-in-one capability. This isn’t just a glass drilling machine—it’s a fully integrated laser glass cutter that supports:

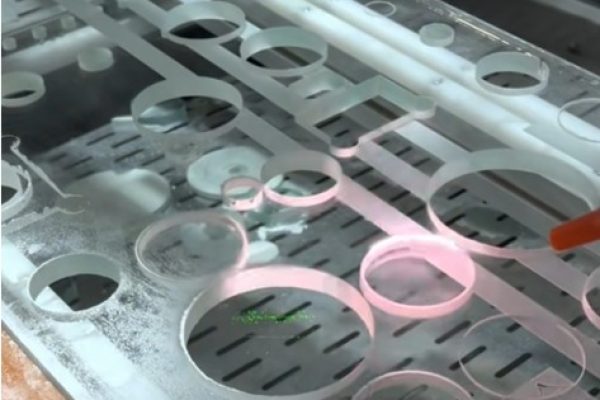

- Glass Drilling: Precisely drill clean round or custom-shaped holes—up to 20mm thickness—without breakage.

- Paint Removal: Strip off paint or coatings from mirrors or glass with zero surface damage.

- Laser Sandblasting Effect: Achieve frosted or textured finishes without using abrasive materials, reducing dust and waste.

- Glass Marking: Add logos, serial numbers, or designs with pinpoint laser precision, even at a minimum height of 0.2mm.

Having all these capabilities in one unit dramatically reduces setup times, eliminates manual transitions between machines, and speeds up overall production.

🔍 High Precision Meets Seamless Control

At the heart of this laser glass processing machine is cutting-edge laser technology, delivering:

- Crisp drilling and marking with ultra-fine accuracy

- Fast operation with minimal downtime

- Automatic red beam alignment for easy setup

The machine’s standard working size is 1300 × 2500 mm, ideal for most architectural and industrial glass panels. Need a larger or unique format? We also support custom sizes based on your specific application.

💡 Applications Across Glass Industries

The Rayno Laser system is designed to serve a wide range of glass processing needs:

- Smart Mirror Production: Cleanly open holes for sensors and remove mirror coatings without damaging the surface

- Interior Design & Architecture: Laser-etch detailed patterns, logos, and frosted effects on glass for walls, partitions, doors, and signage

- Shower Glass and Furniture Glass: Drill precise holes without the risk of cracks or edge chipping

- Touch Panels and Electronics: Perform micro-hole drilling or component marking with exceptional clarity

- Stainless Steel Processing: Mark or engrave non-glass materials, making this machine even more versatile

Whatever your industry, this laser glass cutter adapts to your process—not the other way around.

🚀 Built for Efficiency, Designed for Longevity

With a high-quality laser source and stable mechanical design, this glass drilling machine is engineered for non-stop operation. The constant-temperature water cooling system ensures long service life and thermal stability during extended runs. And with a theoretical laser lifespan of up to 100,000 hours, downtime is kept to a minimum.

Combined with its strong yet compact frame and intelligent positioning system, the Rayno Laser machine offers both durability and ease of use for everyday production.

🛠 Worry-Free Operation with Dedicated Support

Buying equipment is just the beginning. That’s why we back every machine with full lifecycle support:

- 1-Year warranty for the entire machine

- 2-Year warranty for the laser source

- Free lifetime maintenance

- Factory training to ensure you and your team get up and running fast

- 24/7 remote support via WhatsApp, Zoom, phone, or email

- On-site service available globally (travel and lodging at buyer’s expense)

From initial installation to daily operation and emergency support, we’re committed to helping you succeed.

📈 The ROI You’ve Been Looking For

Investing in a Rayno laser glass processing machine means:

- Faster turnaround times

- Fewer rejected products

- Less manual labor

- Streamlined operations

This machine doesn’t just replace outdated methods—it unlocks new possibilities for product design, customization, and industrial scalability.

🔧 Customize Your Laser Glass Cutter Today

Whether you process large panels or require specialty formats, we offer customized work sizes and configurations to fit your factory’s workflow. With a single smart system, you can cut, mark, drill, and decorate glass faster and cleaner than ever before.

Get Started with Rayno Laser

Ready to revolutionize your glass processing with a multi-functional laser glass cutter that combines speed, precision, and versatility?

Visit www.raynolaser.com or contact us at sales@raynolaser.com for a free consultation, demo, or quote. Let’s help your factory reach the next level—with a machine that does more, costs less to run, and delivers results your customers will love.