Rust – the bane of any metal surface. Whether it’s tools, iron structures, or machinery, rust can cause significant damage over time. Understanding how to remove rust effectively and efficiently is crucial for maintaining the longevity and functionality of metal items. This guide will delve into various rust removal methods, with a special focus on the revolutionary laser rust remover technology.

What is Rust and How Does it Form?

Rust is a form of metal oxide that occurs when metal reacts with oxygen and moisture. This electrochemical process results in the familiar reddish-brown flaky coating that weakens and deteriorates metal over time.

Preventing Rust Formation

Preventing rust formation is the best way to avoid the tedious process of rust removal. Here are some preventive measures:

- Keep Metal Dry: Moisture is the primary culprit in rust formation. Store metal items in dry, low-humidity environments.

- Use Protective Coatings: Applying paints, oils, or rust-resistant coatings can create a barrier between the metal and the elements.

- Regular Maintenance: Regularly inspect and clean metal surfaces to prevent the accumulation of rust-causing elements.

Traditional Rust Removal Methods

Manual Rust Removal

Manual rust removal involves using tools like steel brushes and sandpaper.

Advantages:

- Simple and Accessible: Requires minimal equipment.

- Control Over Process: Allows precise rust removal for small areas.

Disadvantages:

- Labor-Intensive: Time-consuming and requires significant physical effort.

- Inconsistent Quality: Hard to maintain consistent results.

- Limited Scope: Suitable only for small areas.

Mechanical Rust Removal

Mechanical methods include shot blasting, sand blasting, and abrasive blasting. These techniques use high-pressure air to propel abrasive materials against the rusted surface.

Advantages:

- Efficient for Large Areas: Suitable for large-scale rust removal.

- Effective: Quickly removes rust and prepares surfaces.

Disadvantages:

- Health Risks: Dust generated can be hazardous to workers.

- Surface Damage: Potential to damage the metal surface.

- Equipment Costs: Requires specialized machinery.

Chemical Rust Removal

Chemical rust removal involves using acids and other chemicals to dissolve rust, known as acid pickling.

Advantages:

- Effective: Can completely dissolve rust.

- Suitable for Complex Shapes: Reaches areas that mechanical methods can’t.

Disadvantages:

- Environmental Impact: Produces toxic waste.

- Health Hazards: Corrosive chemicals can be harmful.

- Disposal Issues: Requires proper disposal of chemicals.

Laser Rust Removal: The Future of Rust Removal

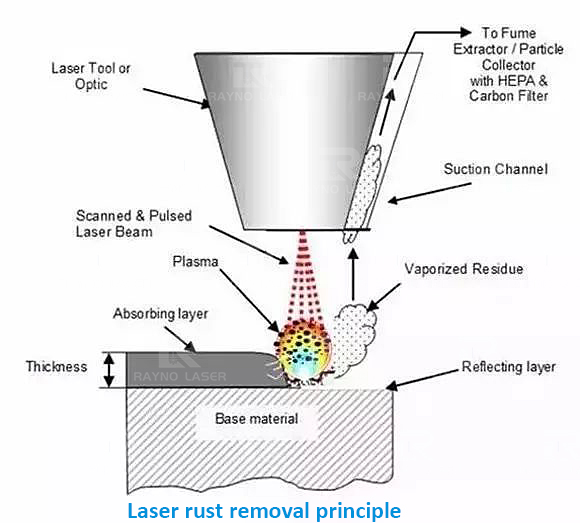

Laser rust removal is a cutting-edge technology that offers a clean, efficient, and environmentally friendly solution. Here’s how it works:

- Absorption of Laser Energy: The laser rust remover utilizes the difference in absorption coefficients between the base material and surface contaminants. The metal and rust absorb the laser energy differently, causing the rust to heat up and expand.

- Thermal Expansion: As the rust expands, the bond between the rust and the metal weakens.

- Vaporization: High-energy laser pulses vaporize the rust, removing it without damaging the underlying metal.

- Ultrasonic Waves: High-frequency laser pulses generate ultrasonic waves that help in breaking the rust layer, enhancing the cleaning process.

Advantages of Laser Rust Removal:

- No Consumables: Unlike chemical and mechanical methods, laser rust removal requires no consumables, making it cost-effective in the long run.

- Eco-Friendly: Produces no chemical waste or pollutants, ensuring an environmentally friendly process.

- Non-Abrasive: The laser does not wear down the metal surface, preserving its integrity.

- Precision Cleaning: Capable of removing even the smallest particles of rust, achieving high cleanliness levels.

- Versatile: Ideal for cleaning hard-to-reach areas and can be used on a variety of surfaces and materials.

- Safety: Eliminates the health risks associated with chemical and mechanical methods.

Disadvantages of Laser Rust Removal:

- Initial Cost: High upfront cost for purchasing laser equipment.

- Training Required: Operators need training to handle the laser equipment safely and effectively.

- Power Requirements: May require substantial power, depending on the scale of cleaning.

Types of Laser Cleaning Machines

There are two main types of laser cleaning machines, based on the beam pattern, each tailored for different applications and environments:

Continuous Laser Cleaning Machines

Continuous laser cleaning machines are designed for high efficiency and are perfect for production lines. Their key features include:

- High Efficiency: Continuous operation ensures real-time, uninterrupted cleaning, making them ideal for high-volume industrial environments.

- Automation: Easily integrated into automated systems, these machines can handle large-scale cleaning tasks with minimal human intervention.

- Consistency: Provides uniform cleaning quality, ensuring that every part meets the same high standards.

- Speed: Capable of handling high-speed cleaning, which is essential for maintaining productivity in fast-paced settings.

Related Products

Pulsed Laser Cleaning Machines

Pulsed laser cleaning machines are known for their precision and versatility, making them suitable for a variety of applications. Key features include:

- Precision Cleaning: Ideal for delicate surfaces and intricate parts, offering fine control over the cleaning process.

- Versatility: Capable of removing rust, oil, paint, and other contaminants from a wide range of materials.

- Adjustable Power: Allows for customization of laser intensity and pulse duration, ensuring optimal results for different cleaning tasks.

- Portable Options: Available in handheld models, providing flexibility and ease of use in various environments, from workshops to field operations.

These laser cleaning machines represent the forefront of rust removal technology, offering unmatched efficiency, precision, and versatility for maintaining metal surfaces.

Applications of Laser Rust Removers

Laser cleaning technology is not limited to rust removal. It can also be used for:

- Paint Stripping: Removing old paint layers from surfaces.

- Oil Cleaning: Cleansing surfaces contaminated with oil and grease.

- Surface Preparation: Prepping surfaces for welding or coating.

- Coating Removal: Stripping off old coatings and layers from various materials.

Understanding how to remove rust from metal effectively is crucial for maintaining the longevity and functionality of metal objects. While traditional methods have their uses, the advent of laser rust removers has revolutionized the field, offering a cleaner, safer, and more efficient solution. Whether you need to remove rust from tools, iron structures, or large-scale industrial equipment, laser cleaning technology is the future of rust removal.

For more information about laser rust removers and other laser cleaning solutions, feel free to contact Rayno Laser via email: sales@raynolaser.com or WhatsApp: +86 13480941847.