Precision Cleaning Without Surface Damage

In the world of industrial cleaning, the demand for precise, efficient, and non-damaging cleaning solutions has surged. Our new pulsed fiber laser cleaning machine is designed to meet these exact needs. With options for 100W, 200W, and 300W fiber lasers, this innovative machine excels in removing paint, rust, and other contaminants from metal surfaces without harming the underlying material.

Key Features of the Pulsed Fiber Laser Cleaning Machine

- Available Laser Powers: 100W, 200W, 300W

- Choose the right power level for your specific needs. The 100W option is ideal for delicate tasks, the 200W fiber laser balances power and precision, and the 300W variant tackles the toughest jobs with ease.

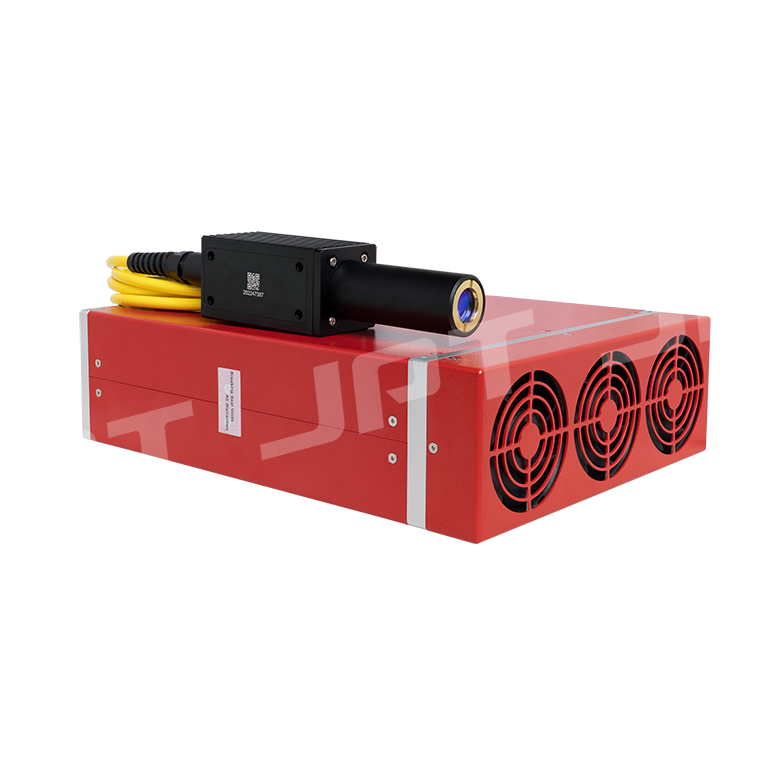

- Air Cooling System

- Efficient air cooling eliminates the need for bulky water cooling systems, ensuring smooth operation and easy maintenance.

- Compact and Lightweight Design

- This machine is only around 30kg, portable and easy to integrate into various workspaces.

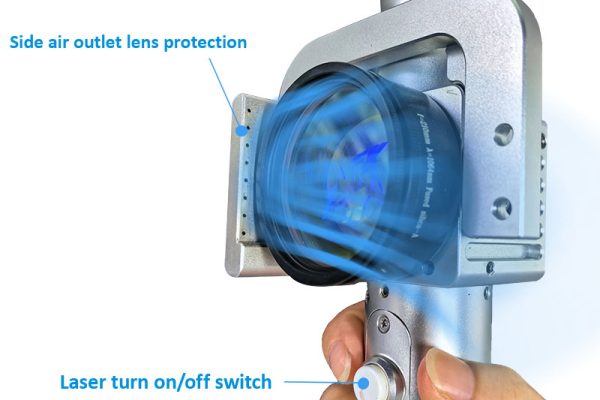

- High-Performance Cleaning Head

- Designed for maximum efficiency, the cleaning head ensures thorough and uniform cleaning, making it suitable for a wide range of applications.

- Adjustable Cleaning Modes

- Offers various cleaning modes to adapt to different needs, ensuring optimal performance for each specific task.

- Minimal Thermal Impact

- The pulsed laser technology minimizes thermal impact on the surface being cleaned, preventing damage and preserving the integrity of the base material.

JPT Laser M7 MOPA Fiber Laser Source 100W 200W for Marking Cleaning

JPT MOPA fiber laser

- Independent frequency adjust range: 1-4000kHz

- Pulse width: 2-500ns, available for metal color marking

- Cooling method: air cooling

- Available laser power: 60W, 100W, 150W, 200W, 300W

Applications of the Pulsed Fiber Laser Cleaning Machine

The versatility of the pulsed fiber laser cleaning machine makes it an invaluable tool across numerous industries. Here are some of its primary applications:

- Laser Paint and Rust Remover

- Efficiently removes paint and rust from metal surfaces without damaging the underlying material. Ideal for automotive, aerospace, and industrial applications.

- Surface Preparation

- Perfect for preparing metal surfaces before painting or coating by removing oxides and other contaminants, ensuring better adhesion and finish.

- Oil and Grease Removal

- Effective in cleaning oil and grease residues from machinery and components, enhancing the efficiency and lifespan of equipment.

- Anode and Coating Stripping

- Precisely removes anodized layers or other coatings without harming the base material, maintaining the quality of the surface.

- Heritage and Antique Restoration

- The non-invasive nature of laser cleaning makes it ideal for restoring valuable antiques and heritage items, removing contaminants while preserving the original material.

Benefits of Using a Pulsed Fiber Laser Cleaning Machine

- Precision and Control

- The pulsed laser provides exceptional control, ensuring that only the unwanted material is removed. This is particularly important in delicate or high-precision applications.

- Efficiency and Speed

- With power options up to 300W, our laser cleaning machine can handle even the toughest jobs quickly and efficiently, reducing operational time and costs.

- Environmental Friendliness

- Laser cleaning is a non-contact, non-abrasive process that doesn’t require chemicals or solvents, making it an environmentally friendly alternative to conventional cleaning methods.

- Cost-Effective

- By reducing the need for consumables like abrasives and chemicals, and minimizing downtime due to its efficiency, the pulsed fiber laser cleaning machine offers a cost-effective cleaning solution.

- Versatility

- The machine’s ability to handle a wide range of contaminants and applications makes it a versatile tool in any industrial setting.

Write at the end

The pulsed fiber laser cleaning machine, with its 100W, 200W, and 300W fiber laser options, represents a significant advancement in industrial cleaning technology. Its precision, efficiency, and ability to clean metal surfaces without thermal damage make it an indispensable tool for removing paint, rust, oil, and other contaminants. Whether you’re in the automotive, aerospace, manufacturing, or heritage restoration industries, this laser cleaning metal solution provides unparalleled performance and reliability.

Investing in a pulsed fiber laser cleaning machine means embracing a technology that not only meets today’s demanding cleaning requirements but also sets the standard for the future of industrial cleaning. Say goodbye to traditional, labor-intensive methods and welcome the power and precision of laser cleaning.