4 in 1 Laser Gun for Handheld laser welder with Dual Wire feeder

- Further improvements in terms of stability, maintainability, etc.,

- Smaller, lighter and more reliable.

- Support dual wire feeder

- Up to 3000W

FOB Reference Price: Get Latest Price

PRODUCT DESCRIPTION

1. Basic features: Self-developed control system with multiple safety alarms, smaller size, flexible operation, and easy to use.

2. More stable: All parameters are visible, the status of the whole machine is monitored in real time, problems can be avoided in advance, troubleshooting and problem solving are more convenient, and the welding joint is ensured to work stably.

3. Process: All parameters are visible, the welding quality is more perfect, the deformation is small, and the penetration is high.

4. Stable parameters and high repeatability: With determined nozzle air pressure and lens status, as long as the laser power is stable, the process parameters must be repeatable. Greatly improve efficiency while also reducing operator requirements.

Main Specifications:

| Input voltage (V) | 220V±10% AC 50/60Hz |

| Installation environment | Flat, no vibration and impact |

| Working environment temperature: (℃) | -10~50℃ |

| Working environment humidity: (%) | <70 |

| cooling-down method | Water cooling |

| Applicable wavelength | 1064nm(±10nm) |

| Applicable power | ≤3000W |

| Collimating lens | D16/F60 |

| Focus | D20/F150 |

| Reflex | 30x14xT2 |

| Protection lens specifications | D18*T2 |

| Maximum air pressure support | 15Bar |

| Focus of vertical adjustment range | ±10mm |

| Scan width-weld | 0~8mm |

| Scan Width-Wash | F150-0~30mm |

| F400-0~60mm | |

| F800-0~120mm | |

| The net weight of the gun | 0.75kg |

TECHNICAL PARAMETERS

Additional information

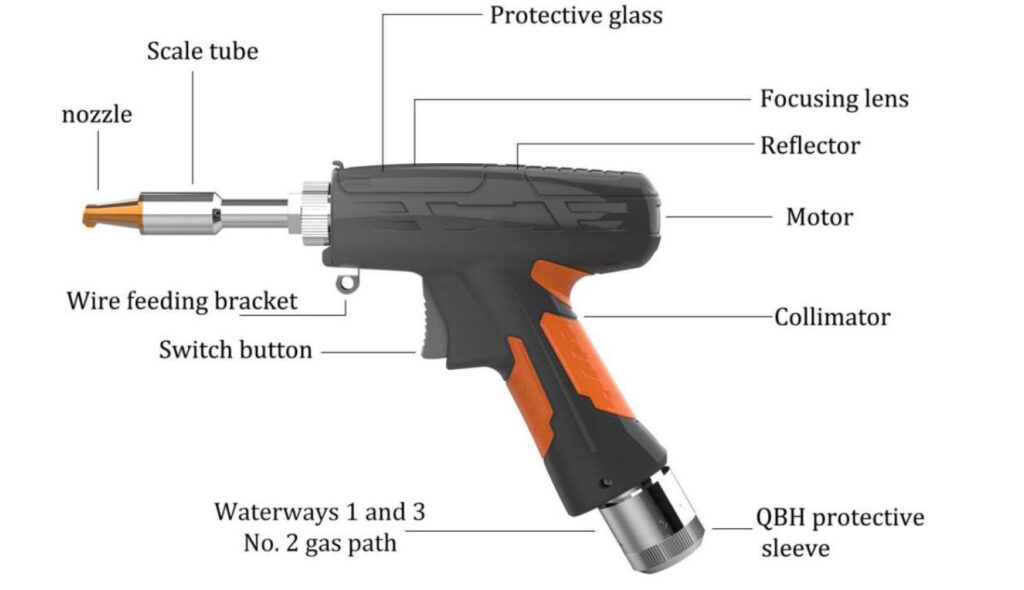

| Fiber interface | QBH |

|---|---|

| Wavelength range | 1070±20nm |

| Rated power | ≤3000W |

| Focus length | 150mm |

| Focus adjustment range | -10mm~+10mm |

| Spot adjustment range | 0~5mm |

| Auxiliary gas pressure | 15Bar |

| Cooling Method | Water Cooling |

| Weight | 0.75KG |

VIDEO

SAMPLE DISPALY

Send your messages to the supplier

Get additional product information or technical support. Our team is always available to provide you with the necessary guidance and solutions.