BOCHU Laser Cutting Head BLT310 for Metal Cutting with FSUCT 2000E

- The BLT 310 Laser Cutting Head is a next-generation solution designed for high-performance, precision-driven laser cutting applications. Combining intelligent monitoring, advanced cooling, and mechanical safety systems, the BLT 310 sets a new benchmark in cutting head performance.

FOB Reference Price: Get Latest Price

PRODUCT DESCRIPTION

The BLT 310 Laser Cutting Head is a next-generation solution designed for high-performance, precision-driven laser cutting applications. Combining intelligent monitoring, advanced cooling, and mechanical safety systems, the BLT 310 sets a new benchmark in cutting head performance.

Whether you’re handling high-speed production or working in challenging environments, the BLT 310 delivers consistent results, minimal maintenance, and unparalleled ease of use.

Key Features & Benefits

1. Advanced Water Cooling System

Stable Cutting, Long-Term Durability

The BLT 310 utilizes a high-efficiency water-cooling system to maintain optimal thermal performance during extended cutting operations.

-

Internal water pathways are coated with a corrosion-resistant layer

-

Prevents internal scaling, corrosion, and clogging

-

Maintains cooling efficiency for consistent and reliable performance

2. Protective Window Temperature Monitoring

Real-Time Detection for Maximum Safety

A built-in temperature sensor continuously monitors the protective window’s condition.

-

Detects contamination or overheating instantly

-

Automatically shuts down the laser and triggers an alert

-

Significantly reduces the risk of window breakage and system downtime

3. Gas Pressure Monitoring Sensor

Greater Stability, Cleaner Cuts

Stable gas flow is essential for clean, accurate laser cutting. The BLT 310 features a pressure sensor that ensures consistent gas output.

-

Monitors gas pressure in real time

-

Prevents quality fluctuations due to gas instability

-

Improves reliability in high-precision applications

4. Quick and Easy Focus Adjustment

Higher Efficiency with Vertical Collimation

Focusing adjustments are fast and precise, thanks to a vertical collimation mechanism.

-

Simplifies the focus-setting process

-

Enables quick transitions between materials or thicknesses

-

Boosts overall operational efficiency

5. Amplified Capacitive Sensor

Precision Cutting at Its Finest

To ensure pinpoint accuracy during high-speed operations, the BLT 310 integrates an enhanced capacitive sensor system.

-

Amplified signal processing improves sensor sensitivity

-

Allows for highly responsive height following

-

Maintains cutting precision even on uneven surfaces

6. Anti-Collision Protection

Simplified Maintenance, Reduced Downtime

Unexpected collisions during operation can damage the cutting head and lead to costly downtime. The BLT 310 includes a physical safety design to protect itself.

-

Impact-absorbing protection screws safeguard the unit

-

Minimizes risk of internal damage during collisions

-

Allows for quick, on-site recovery without factory repair

Why Choose the BLT 310?

The BLT 310 isn’t just another laser cutting head—it’s a comprehensive solution engineered for high precision, long-term reliability, and minimal operator intervention. With built-in safety, real-time monitoring, and fast adjustment capabilities, it empowers manufacturers to operate with confidence, speed, and control.

Ideal for industries including:

-

Precision sheet metal cutting

-

Industrial fabrication

-

Automotive parts processing

-

Aerospace materials machining

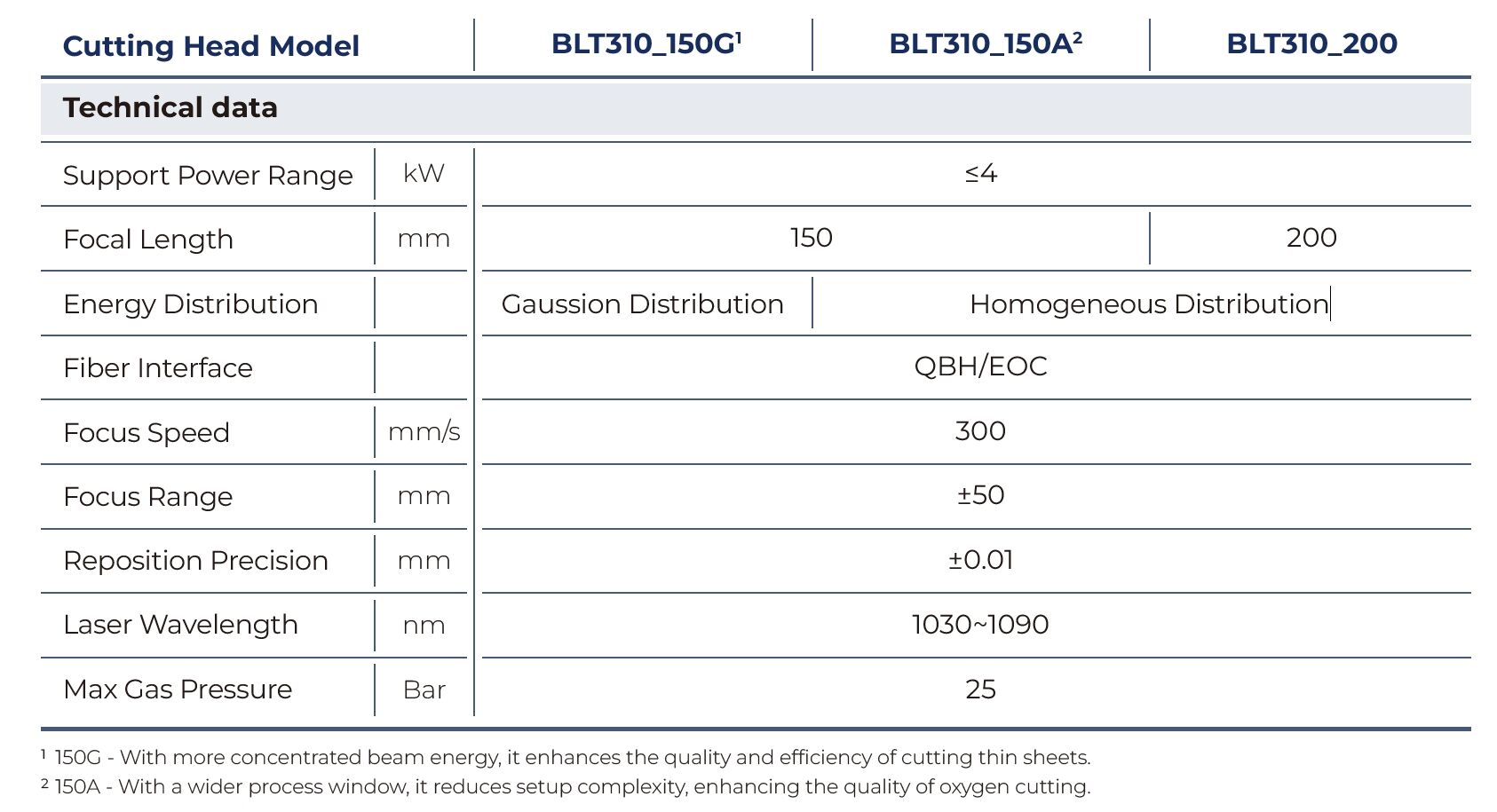

TECHNICAL PARAMETERS

Additional information

| Cutting Mode | 2D |

|---|---|

| Focusing Length | F150mm, F200mm |

| Auto focus range | +/-40mm |

| Auto focus speed | 300mm/s |

| Accuracy | 0.01mm |

| Nozzle specifications | single layer, double layer, non-standard |

| Fiber Interface | QBH, EOC |

| Weight | 4kg |

| Model | BLT310, BLT310+FSCUT 2000E, BLT310+FSCUT 2000E+Laser Source |

VIDEO

SAMPLE DISPALY

Send your messages to the supplier

Get additional product information or technical support. Our team is always available to provide you with the necessary guidance and solutions.