BWT CW6000 6KW Laser Source for laser cutting

BWT 6000W Fiber Laser Source combines exceptional power stability, superior beam quality, and a rugged design to deliver unmatched performance across industrial applications. Whether integrated into handheld laser welding machines or metal laser cutting machines, this versatile solution enhances productivity and precision for businesses seeking reliable and cost-efficient laser technology.

FOB Reference Price: Get Latest Price

PRODUCT DESCRIPTION

The BWT BFL-CW6000 Fiber Laser Source is a high-performance solution designed for precision industrial applications, including handheld laser welding machines, fiber laser welding machines. This laser source ensures excellent beam quality, high power stability, and versatility, making it ideal for advanced manufacturing processes like laser cutting, laser welding, laser cladding, and sheet metal processing.

Technical Specifications of BWT 6KW fiber laser source

Below is a detailed table of the Raycus 6000W Fiber Laser Source’s specifications:

| Category | Parameter | Specification |

| Optical Characteristics | Power | 6000 W |

| Wavelength Range | 1080 ± 10 nm | |

| Fiber Core Diameter | 50μm, 100μm or Customizable | |

| Fiber Cable Length | 25m or Customizable | |

| Output Connector | QBH | |

| Indicator Light | Red | |

| Operating Mode | Continuous or Modulation | |

| Polarization Direction | Random | |

| Output Power Stability (25°C) | < ± 1.5% (2h) | |

| Power Adjustment Range | 10%-100% | |

| Maximum Modulation Frequency | 5 kHz | |

| Mechanical Dimensions and Weight | Weight | ~67 Kg |

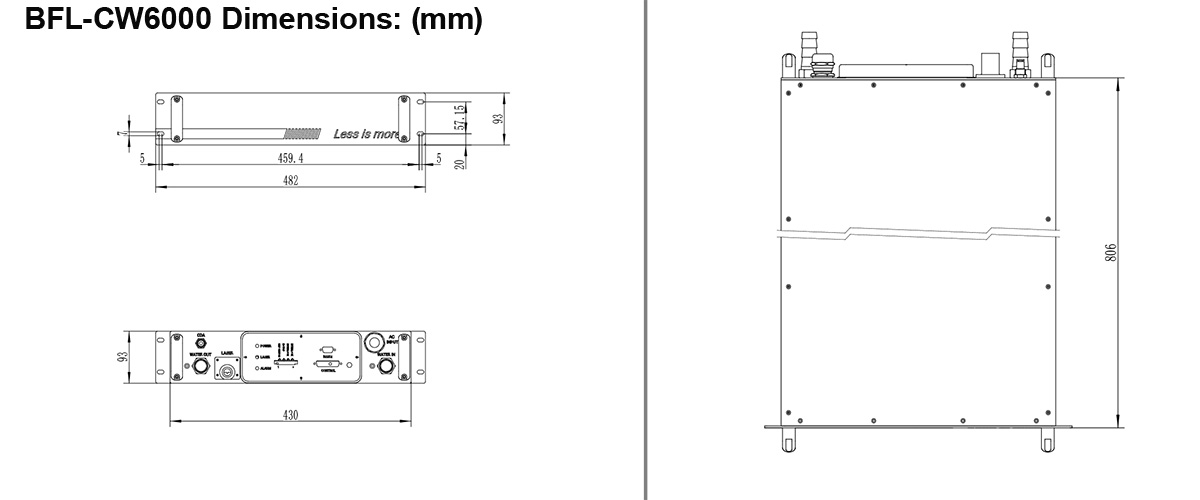

| Dimensions (H*W*D) | 93mm × 482mm × 806mm | |

| Electrical Characteristics | Voltage | 380 ± 20V, AC, PE, 50/60Hz |

| Power Consumption | 18.0 kW | |

| Control Method | RS232/AD | |

| Cooling Parameters | Cooling Capacity Requirement | 13.0 kW |

| Set Temperature | 22°C (Laser Module), 30°C (QBH) | |

| Pipe Diameter (Inner) | Φ25 mm | |

| Cooling Water Flow Rate | > 55 L/min | |

| QBH Cooling Water Flow Rate | 1.5–2.0 L/min |

6KW Laser Source Size

Key Features of BWT 6kw laser source

- Low Cost and Maintenance-Free: The BWT 6000W laser source delivers exceptional value with a highly efficient design that reduces operating costs and requires no maintenance.

- Superior Power Stability: Ensures consistent performance for precision applications, providing high reliability during extended operations.

- High-Quality Beam: With near-diffraction-limited beam quality, the laser can be focused to a fine point, enabling precise and efficient processing.

- Adjustable Modulation Frequency: Supports a maximum modulation frequency of up to 5kHz, allowing greater flexibility for different applications.

- Robust and Durable: Featuring a modular, all-fiber design, the laser source is housed in a sturdy enclosure to withstand harsh industrial environments.

BWT 6kw laser source Applications

The BWT BFL-CW6000 laser source is widely used in the following fields:

- Laser Welding: Perfect for integration into handheld and portable laser welding machines, offering seamless welding of metals like steel, aluminum, nickel-based alloys, and titanium alloys.

- Laser Cutting: Suitable for metal laser cutting machines, delivering high precision for sheet metal processing and cutting.

- Laser Cladding: Enables the addition of coatings on metal surfaces, improving durability and performance.

- Sheet Metal Processing: Ideal for high-quality cutting, welding, and finishing of various sheet metals.

TECHNICAL PARAMETERS

Additional information

| Laser Type | CW fiber laser |

|---|---|

| Laser Power | 1500W, 2000W, 3000W, 6000W |

| Application | Used for laser cutting, cleaning, laser welding, laser cladding, laser brazing, laser surface heat treatment |

VIDEO

SAMPLE DISPALY

Send your messages to the supplier

Get additional product information or technical support. Our team is always available to provide you with the necessary guidance and solutions.