Collaborative Robot Laser Welding Machine

The Collaborative Robot Laser Welding Machine combines advanced robotic laser welding technology with intuitive, safe human-robot collaboration. Featuring easy programming by demonstration, high-precision laser welding, and a compact, flexible design, it delivers consistent weld quality with minimal setup time. This smart robotic welding machine is ideal for efficient, adaptable robotic welding automation across diverse manufacturing applications.

FOB Reference Price: Get Latest Price

PRODUCT DESCRIPTION

The Smart Solution for Flexible, High-Precision Robotic Welding Automation

In today’s competitive manufacturing environment, companies are under constant pressure to improve welding quality, increase productivity, and reduce dependence on skilled labor. Traditional welding robots, while powerful, often lack flexibility and require complex programming, high safety infrastructure, and long deployment cycles. Our Collaborative Robot Laser Welding Machine offers a smarter alternative—combining advanced robotic laser welding technology with intuitive operation, built-in safety, and unmatched production flexibility.

This next-generation robotic welding machine is designed for manufacturers seeking efficient, scalable, and cost-effective robotic welding automation without the limitations of conventional industrial welding robots.

A New Generation of Robotic Welding Systems

Unlike traditional welding robots that must operate inside fenced-off cells, our collaborative robotic welding system is engineered for safe human-robot collaboration. Integrated torque sensors on every joint enable real-time collision detection, allowing the robot to stop instantly upon contact. This eliminates the need for bulky safety cages and allows operators to work side by side with the robot in the same workspace.

The result is a compact, space-saving robotic welding solution that reduces installation costs, shortens commissioning time, and enables rapid integration into existing production lines.

Easy Programming: Teach by Hand, Weld with Precision

One of the most powerful advantages of this robotic welder is its simplified programming approach. Traditional industrial welding robots often require specialized engineers and complex coding, which can slow down production and increase costs. Our collaborative robot eliminates this barrier through intuitive “teach-by-demonstration” programming.

Operators can manually guide the robot arm to define welding paths, angles, and start and end points. The system automatically records and reproduces these movements with high accuracy. Even operators with no prior robot programming experience can quickly create reliable welding programs.

This capability dramatically reduces setup time—from hours to minutes—and makes the system ideal for small-batch production, frequent product changes, and customized manufacturing. For advanced applications, optional vision systems and intelligent positioning functions allow semi-automatic or one-click welding, further improving efficiency.

Two different robotic arms with varying load capacities and arm lengths are available.

| Model | FR5 | FR10 |

| Payload | 5kg | 10kg |

| Reach | 922mm | 1400mm |

| Repeatability | ±0.02mm | ±0.05mm |

| Typical average power | 261W | 294W |

| Typical peak power | 314W | 503W |

| Number of joints | 6-axis | 6-axis |

| IP classification | IP54 (IP65 optional) | IP54 (IP65 optional) |

High-Performance Laser Welding Technology

At the heart of the system is a powerful fiber laser welding machine, available in multiple power configurations to suit different production needs. Laser welding delivers highly concentrated energy, producing deep penetration and clean, narrow weld seams with minimal heat input.

Compared with traditional arc welding, robotic laser welding offers significant advantages:

-

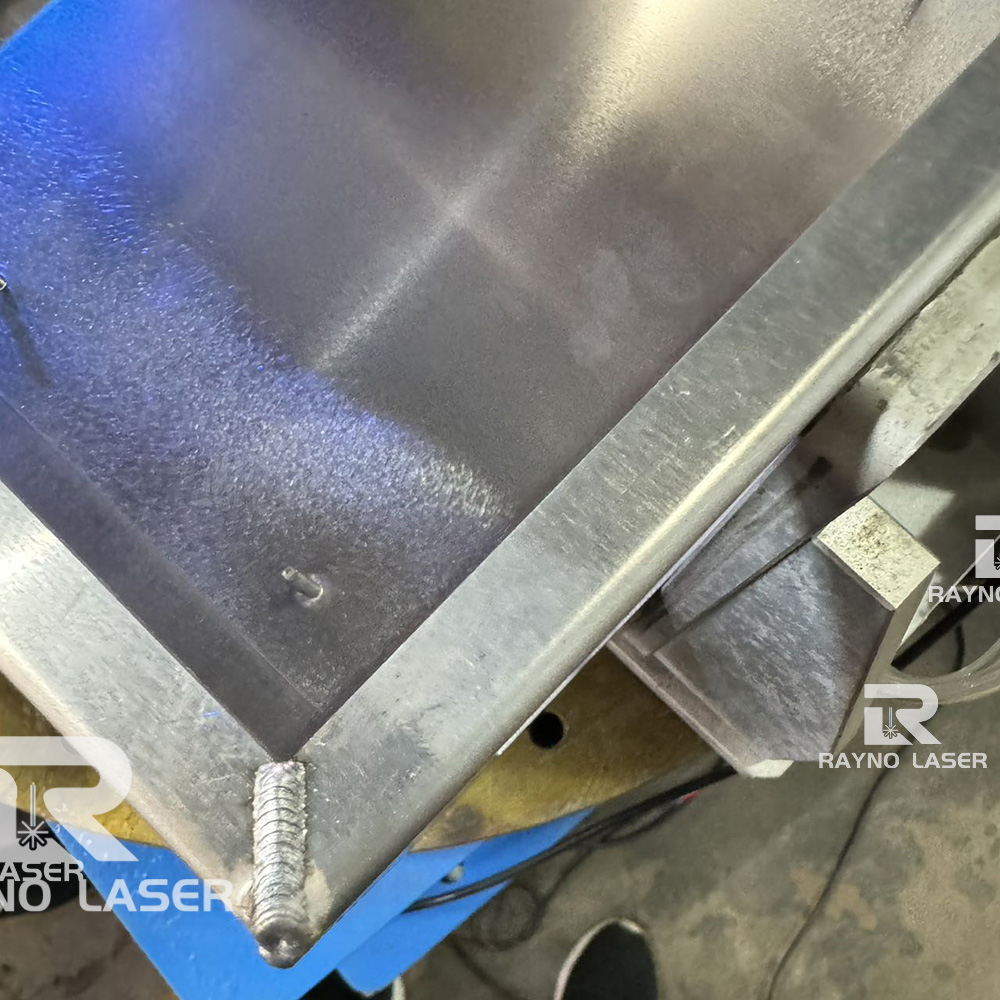

Superior weld appearance with smooth, uniform seams

-

Minimal heat-affected zone and extremely low material deformation

-

Reduced spatter and minimal post-weld finishing

-

Consistent, repeatable weld quality independent of operator skill

When combined with the collaborative robot’s high positioning accuracy and repeatability, the system ensures stable welding performance across long production runs.

Flexible Welding for Multiple Materials and Applications

This robotic welding automation solution is designed to handle a wide range of materials and welding tasks. It supports continuous and modulated laser welding modes, with optional oscillation functions to improve gap tolerance and weld strength.

The system is suitable for welding:

-

Carbon steel and stainless steel

-

Aluminum alloys

-

Copper and aluminum dissimilar materials

An integrated process database allows users to quickly select optimized welding parameters for different materials and thicknesses, typically up to 8 mm depending on application. This flexibility makes the system a practical choice for manufacturers serving diverse markets and product lines.

Compact Design, Maximum Production Flexibility

Unlike large, fixed welding robots, this collaborative robotic welding machine features a compact footprint and optional mobile configuration. It can be easily repositioned between workstations or production lines, enabling manufacturers to respond quickly to changing production demands.

Standard industrial power requirements and a modular system design make integration simple and cost-effective. Whether used as a standalone robotic welding system or as part of a larger automated production line, the machine delivers reliable performance with minimal infrastructure changes.

Industry Applications

Thanks to its versatility and ease of use, the collaborative robot laser welding machine is widely applied across multiple industries:

Automotive and Auto Parts Manufacturing

Ideal for welding frames, brackets, battery housings, and structural components, improving consistency while reducing labor costs.

3C Electronics and Precision Components

Perfect for thin materials and precision assemblies such as electronic enclosures and device frames, where accuracy and appearance are critical.

Home Appliances and Sheet Metal Fabrication

Delivers clean, high-strength welds for panels, cabinets, and housings with minimal distortion.

Medical Devices and High-Value Products

Laser welding’s precision and cleanliness meet the strict quality standards required for medical and high-end applications.

Why Choose a Collaborative Robotic Welder?

Compared with traditional welding robots, this collaborative solution offers faster deployment, lower total cost of ownership, and significantly greater flexibility. It empowers manufacturers to adopt robotic welding automation without the complexity and rigidity of conventional systems.

By combining intuitive programming, advanced safety features, and high-performance laser welding technology, this system enables manufacturers to improve productivity, maintain consistent quality, and remain competitive in rapidly changing markets.

TECHNICAL PARAMETERS

Additional information

| Laser Power | 1500W, 2000W, 3000W |

|---|---|

| Collaborative Robot Payload | 5KG, 10KG |

| Cooling Method | Air Cooling, Water Cooling |

| Aiming and Positioning | Red Beam |

| Laser Head | NS, SUP |

| Working Voltage | 220±20V,AC,PE,50/60Hz, 380V, 50/60Hz |

| Number of joints | 6 axis |

| Collaborative Robot Arm Reach | 922mm, 1400mm |

VIDEO

SAMPLE DISPALY

More machine information, please contact us now.

Email: sales@raynolaser.com

More machine information, please contact us now.

Email: sales@raynolaser.com Send your messages to the supplier

Get additional product information or technical support. Our team is always available to provide you with the necessary guidance and solutions.