Laser Robot with Robotic Arm for Robot Welding

The RN-RW Series advanced laser welding robot offers precision, speed, and versatility, designed for industries like automotive, aerospace, and medical equipment. Featuring high-quality robotic arms from brands like Fanuc and YASKAWA, it welds materials such as stainless steel, carbon steel, aluminum, and more. With fast welding speeds, multi-axis capability, and low-maintenance operation, it delivers consistent, strong welds. Customizable for any setup, this robot welding machine is the efficient, reliable choice for modern metal processing.

FOB Reference Price: Get Latest Price

PRODUCT DESCRIPTION

The RN-RW series Laser Welding Robot is a latest solution in modern manufacturing, built to deliver unparalleled precision, efficiency, and durability for various metal welding applications. With the option to customize robotic arms from industry-leading brands like Fanuc, ABB, YASKAWA, and KUKA, this robot welding machine offers unmatched versatility and flexibility, transforming how industries approach high-precision welding tasks.

From automotive and aerospace to medical equipment and home appliances, this laser robot is a powerful addition to any production line needing accurate, high-speed, and consistent welding. Here’s what makes this robotic welding solution a game-changer in today’s industrial landscape.

Wide Material Compatibility of Laser Welding Robot

This laser robot for welding is optimized for a range of metals, making it incredibly versatile. It can seamlessly weld stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloys, as well as galvanized and aluminum-zinc coated plates. This compatibility makes it ideal for high-stress applications where material strength and corrosion resistance are crucial.

Versatile Applications of Robotic Welding Across Industries

The applications for this robot welding machine span multiple industries:

- Aerospace & Automotive: Achieve strong, reliable welds on lightweight alloys and complex metal parts.

- Machinery & Elevator Manufacturing: Enhance efficiency in structural welding and parts assembly.

- Medical Equipment & Electronics: Ensure precise, high-quality welds for parts where precision is critical.

- Home Appliances & Fitness Equipment: Deliver sturdy, long-lasting joins with smooth and visually appealing finishes.

- Custom Metal Fabrication: Enable complex, multi-position welding setups to serve diverse production needs.

With such broad application possibilities, this laser robot meets the demands of both large-scale industrial production and specialized, custom welding jobs, making it an excellent solution for companies seeking to upgrade their manufacturing processes.

Key Features and Benefits of Robotic Welding

1. Seamless, Multi-Axis Welding

Equipped with advanced robotic arms, this robot welder offers multi-axis movement, allowing for high flexibility in welding angles and positions. The multi-position and multi-axis capability make it perfect for accessing difficult angles or hard-to-reach spots, offering the level of precision needed for intricate welding tasks. This capability is crucial for industries like automotive and aerospace, where complex parts require detailed welding.

2. Fast Welding Speeds and Minimal Heat Distortion

The robotic welding machine operates at remarkable speeds, welding thicknesses between 0.5mm and 8mm with a minimal heat-affected zone. This feature not only reduces metal deformation but also enhances the visual and structural quality of the weld. The result is smooth, strong, and aesthetically pleasing welds, making it suitable for applications where both function and appearance are essential.

3. Efficient, Low-Maintenance Operation

The laser robot for welding stands out for its efficiency. Unlike traditional YAG laser welders or gas arc welding machines, it consumes only one-eighth of the energy, making it extremely cost-effective. Additionally, this robot welder requires no consumables, and its long lifespan—up to 100,000 hours—ensures reliable, low-maintenance operation. For businesses, this translates into significant cost savings and a lower environmental impact.

4. User-Friendly and Labor-Saving

This robotic welding system is designed with simplicity and user-friendliness in mind. The intuitive operation reduces the need for extensive training, making it accessible for operators of varying skill levels. Its automation capabilities reduce labor demands, helping factories lower operational costs while boosting productivity and enhancing overall workplace safety.

5. Customizable Options for Any Production Line

Customization options allow users to tailor the laser robot to specific production requirements. The robotic arm length and work table are fully adjustable, ensuring a seamless fit within any production setup. This flexibility makes it easy to integrate into existing workflows and adapt to various tasks and materials.

Technical Specifications

Below is a detailed overview of the laser robot’s specifications, providing insights into its performance capabilities:

| Parameter | Specification |

|---|---|

| Laser Wavelength | 1070 ± 10 nm |

| Working Mode | Continuous/Pulse |

| Recommended Welding Thickness | Stainless/Carbon Steel: 0.5-8 mm |

| Welding Gap Requirement | < 0.5 mm |

| Repeat Positioning Accuracy | ± 0.05 mm |

| Aiming Positioning Method | Red Light Indicator (Optional CCD) |

| Total Power | 5-20 KW |

| Operating Voltage | AC220V/380V, 50-60 Hz |

| Optional Power Range | 1000-4000 W |

| Spot Size | 0.2-5 mm (Adjustable) |

| Robotic Arm Length | 930 mm (Optional Extension) |

| Work Table | Customizable |

Why Choose This Laser Welding Robot?

When it comes to robotic welding solutions, this laser robot stands out for its combination of precision, flexibility, and energy efficiency. The inclusion of high-quality, customizable robotic arms from renowned brands like Fanuc, ABB, YASKAWA, and KUKA ensures durability and compatibility with various industrial applications. Its speed, reliability, and intuitive operation make it an invaluable asset to any manufacturing environment where quality and efficiency are top priorities.

By integrating this robotic welding machine into your production line, you can enhance your output, reduce waste, and minimize labor costs, all while maintaining consistent quality across each welded piece. Its multi-axis capability, minimal maintenance requirements, and extensive material compatibility make it an excellent choice for businesses looking to innovate and stay competitive.

This laser welding robot offers a powerful solution for companies looking to optimize their welding processes, whether for large-scale production or intricate custom fabrication. With its impressive durability, flexibility, and energy-saving features, it’s more than just a machine—it’s a partner in your production success.

TECHNICAL PARAMETERS

Additional information

| Laser Power | 1000W/1500W/2000W/3000W, 4000W |

|---|---|

| Cooling Method | Water Cooling |

| Aiming and Positioning | Red Beam |

| Laser Head | Raytools, WSX, Relfar, SUP |

| Working Voltage | 220±20V,AC,PE,50/60Hz, 380V, 50/60Hz |

| Machine Weight | Robotic arm 260KG + Control cabinet 160KG |

VIDEO

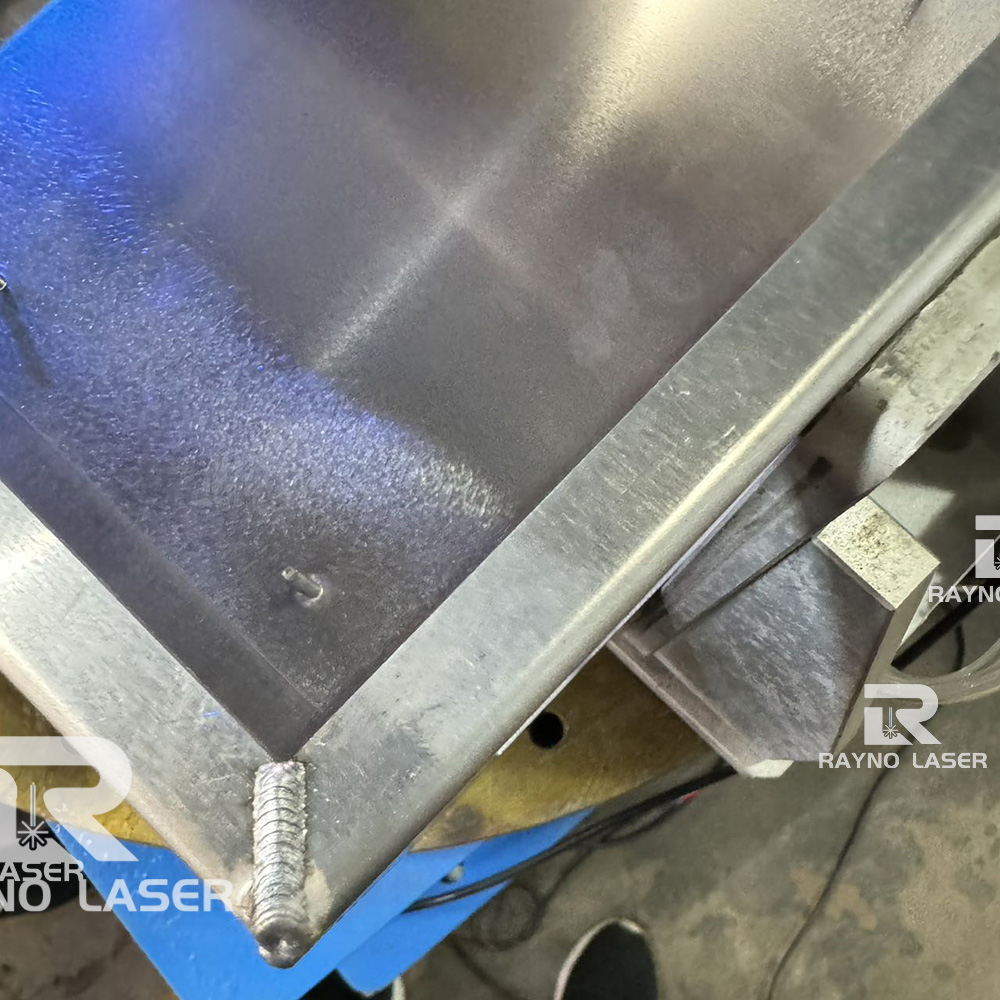

SAMPLE DISPALY

More machine information, please contact us now.

Email: sales@raynolaser.com

More machine information, please contact us now.

Email: sales@raynolaser.com Send your messages to the supplier

Get additional product information or technical support. Our team is always available to provide you with the necessary guidance and solutions.