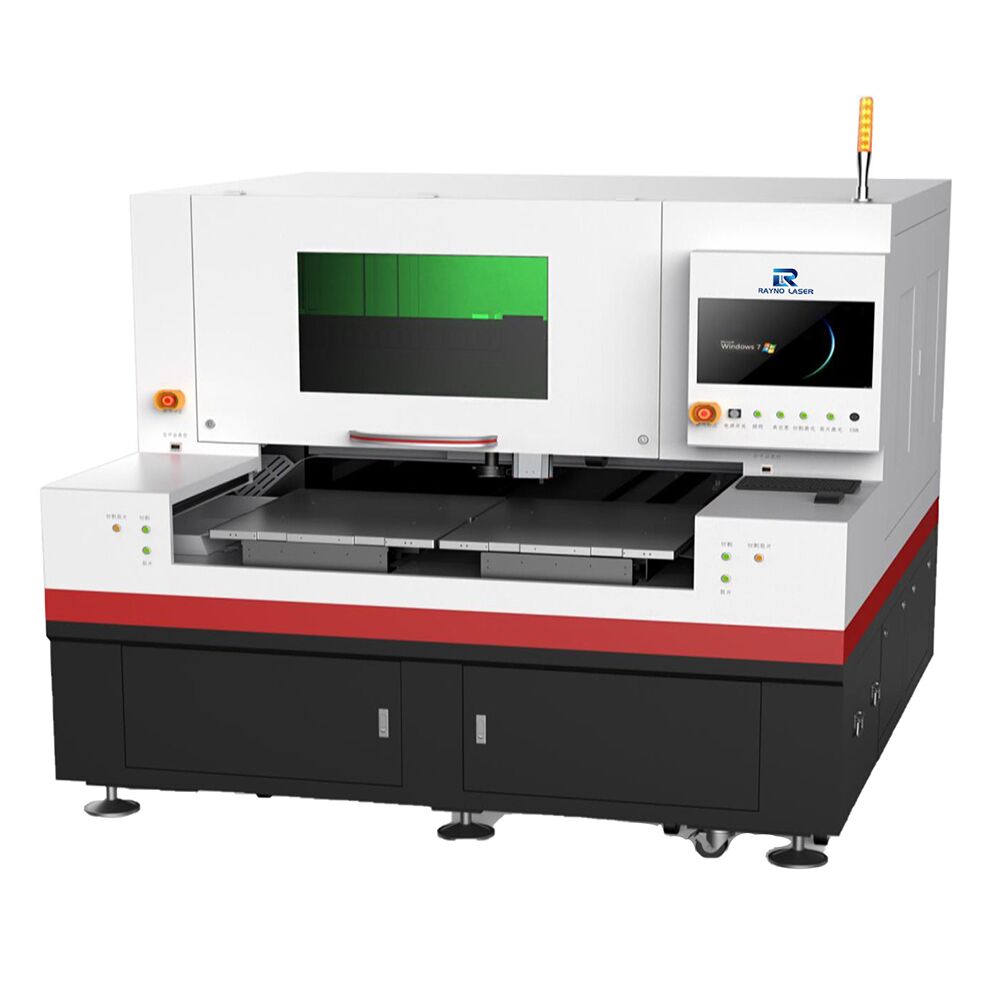

Picosecond Laser Glass Cutting Machine for Glass Cutting and Spliting

Rayno Laser picosecond laser glass cutting machine offers an advanced solution ultra-clear glass, borosilicate glass, and quartz glass cutting, making it ideal for applications such as smartphone covers, automotive glass, and LCD screens. It combines glass cutting and splitting. With high efficiency, reduced costs, and eco-friendly operation, this machine sets a new standard for glass cutting in electronics, automotive, and optical industries.

FOB Reference Price: Get Latest Price

PRODUCT DESCRIPTION

Main Features of picosecond laser glass cutting machine

1.The glass cutting machine is capable of cutting large thicknesses of material, with a maximum cutting thickness of 19mm for ultra-white glass.

2.It offers higher cutting efficiency and can reach maximum cutting speeds of up to 500mm/s, which is several times the processing efficiency of CNC.

3.No secondary processing is required. Minimal edge collapse, no secondary processing such as flushing, grinding, and polishing is required.

4.Smooth and flat without damage: neat edges, good verticality, no micro-cracks, breakage or fragments.

5.Higher edge strength: picosecond laser, so the edge strength is higher, three times that of traditional cutting methods.

6.Environmentally friendly and no consumables: non-contact cutting, energy saving and environmental protection.

7.Cutting accuracy ≤20μm, can flexibly realize various types of glass special-shaped cutting

Laser Glass Cutting Machine Advantages

| Aspect | Laser Glass Cutting Machine | Traditional CNC Cutting |

| Cutting Quality | High cutting strength with minimal edge chipping | Prone to chipping and edge damage |

| Precision | Industry-leading precision, taper-free cutting | Limited precision due to tool wear |

| Tool Wear | Tool-free processing, no wear issues | High tool wear (e.g., drill bits, blades) |

| Environmental Impact | Eco-friendly, no cutting fluids needed | Requires cutting fluids, causing environmental pollution |

| Efficiency | High production efficiency with faster processing speeds | Low efficiency, slower processing speeds |

| Operational Costs | Lower operational costs with reduced resource needs | High costs due to tool replacement, manpower, and equipment |

| Space Requirements | Compact design, optimized for smaller spaces | Requires more equipment and larger workspace |

| Manpower | Minimal manpower needed | High labor demand |

| Suitability for Brittle Materials | Designed specifically for brittle materials like glass | Limited capability, struggles with fragile glass materials |

| Consistency | Highly consistent and repeatable results | Variability due to manual intervention and tool degradation |

Picosecond laser glass cutting machine Parameters

| Category | Dual Platform Glass Cutting & Splitting Integrated Machine | Single Platform Glass Cutting Machine | |

| Cutting Laser Source | Laser Type | Picosecond Pulse Laser | |

| Power | 50W (Optional: 30W/60W/80W) | ||

| Wavelength | 1064nm, Beam Quality: M2<1.3 | ||

| Pulse Width | <10PS | ||

| Cooling Method | Water Cooling | ||

| Cutting Head | Focusing Head | Top brand Lens Focusing Head | |

| Cutting Head Quantity | Single Head | ||

| Focus Spot Size | <2μm | ||

| Cutting Performance | Cutting Speed | 0-500mm/s Adjustable | |

| Cutting Thickness | ≤19mm (Thickness may vary depending on material; thicker materials can use multi-blade cutting) | ||

| Minimum Cutting Edge | <5μm | ||

| Cutting Accuracy | ≤20μm | ||

| X/Y Cutting Range | 600mm x 700mm Dual Platform | 600mm x 700mm Single Platform | |

| Splitting Laser Source | Laser Type | Continuous Laser | None (Optional external splitting device) |

| Power | 150W (Optional: 100W/120W/300W) | ||

| Wavelength | 10.6μm | ||

| Pulse Width | Pulse Frequency: 1Hz-100kHz | ||

| Cooling Method | Water Cooling | ||

| Focusing Lens | F63.5 Focusing Lens | ||

| Splitting Head | Splitting Head Quantity | Single Head | None |

| Focus Spot Size | 3mm (Reference: 2-5mm, adjustable based on splitting thickness) | ||

| Electrical Platform | X/Y Drive System | Direct Drive Motor, 0.1μm Digital Grating Scale | |

| X/Y Travel Range | X1200mm, Y700mm | X700mm, Y600mm | |

| X/Y Movement Speed | Maximum 1000mm/s, Acceleration 1G | ||

| X/Y Repeat Positioning Accuracy | ≤±2μm | ||

| X/Y Positioning Accuracy | ≤±1μm | ||

| Z-Axis Drive System | Servo Motor | ||

| Z-Axis Travel Range | 100mm | ||

Laser glass cutting machine Application:

Rayno Laser advanced laser glass cutting machine is designed to handle a wide range of brittle and precision materials, making it ideal for various industries and applications, including:

- Material Types:

- Ultra-clear glass

- Plain white polymer

- High borosilicate glass

- Quartz glass

- K9 glass

- Product Applications:

- Smartphone glass covers

- Camera glass covers

- Automotive glass

- Specialized Applications:

- LCD screen cutting

- Optical filter cutting

- Mirror cutting

This versatile solution ensures high precision, minimal edge chipping, and superior cutting quality across all these materials and applications. It is the perfect choice for industries such as consumer electronics, automotive, and optics.

TECHNICAL PARAMETERS

Additional information

| Laser Power | Picosecond Laser 30W, Picosecond Laser 50W, Picosecond Laser 60W, Picosecond Laser 80W |

|---|---|

| Cooling Method | Water Cooling |

| Machine Weight | 2000-4000KG |

VIDEO

SAMPLE DISPALY

Send your messages to the supplier

Get additional product information or technical support. Our team is always available to provide you with the necessary guidance and solutions.