SUP23T Four-in-One Handheld Laser Welding Head

The SUP23T combines welding, cutting, cleaning, and seam cleaning in one lightweight handheld head. Supporting fiber laser sources up to 3000W, it delivers stable welds, precise cuts, and efficient cleaning with minimal spatter. With its ergonomic design, real-time safety monitoring, and versatile applications, the SUP23T is the ultimate all-in-one tool for modern metal processing and repair industries.

FOB Reference Price: Get Latest Price

PRODUCT DESCRIPTION

SUP23T Four-in-One Handheld Laser Welding Head (≤3000W)

The SUP23T Handheld Laser Welding Head is a powerful and versatile 4-in-1 tool designed for modern manufacturing. With support for welding, cleaning, cutting, and post-weld seam cleaning, it provides unmatched flexibility and efficiency in one compact device. Built for precision and reliability, it is compatible with fiber laser sources up to 3000W, making it the ideal choice for industries that demand performance and versatility.

Key Features

1. Perfectly Safe

The SUP23T is equipped with an independently developed security detection system, offering multiple safety alarms and enhanced stability. Operators can weld with confidence knowing the system is safeguarded against risks.

2. Efficient and Convenient

Designed for time-saving operations, the head integrates a focus mirror and collimation mirror with a drawer-style replacement structure. This makes maintenance quick and easy, reducing downtime in busy production environments.

3. Light and Ergonomic

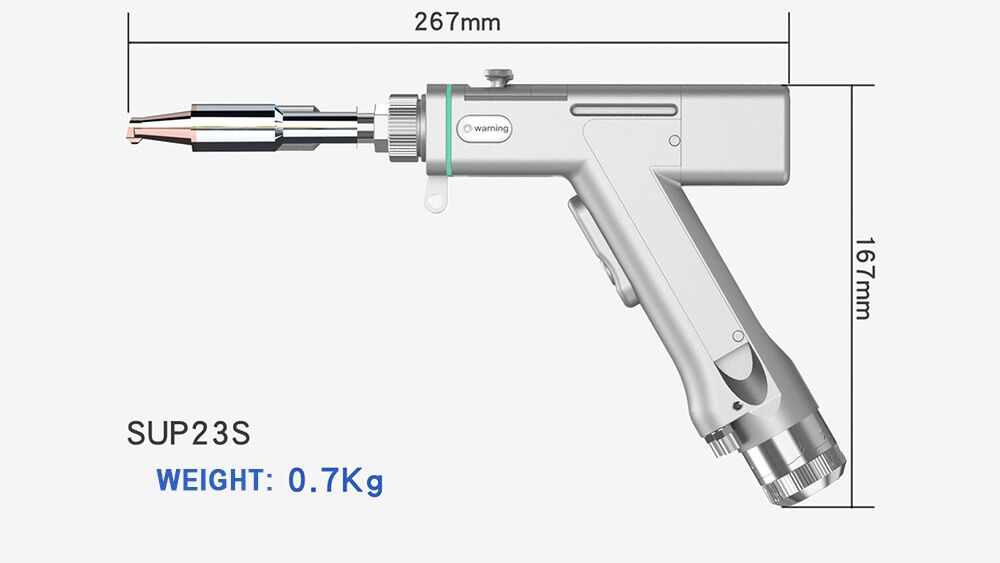

Weighing only 0.7 kg, the SUP23T is lightweight, portable, and easy to handle. Its ergonomic design improves comfort, enabling operators to work longer without fatigue.

4. Stable and High-Quality Welding

The optimized optical structure ensures high welding strength, low deformation, and deep penetration. Whether welding stainless steel, carbon steel, aluminum, or other metals, the results are clean and consistent.

5. Multi-Functional Performance

With four modes—welding, cleaning, cutting, and pass cleaning—this handheld laser welding head replaces multiple tools in your workshop. It supports continuous welding, spot welding, seam cleaning, rust removal, and manual or automatic cutting. All functions are monitored in real time, ensuring precision and reliability.

Technical Parameters

-

Scope of Application: ≤3000W fiber laser systems

-

Collimating Focal Length: D16 F60 mm

-

Focusing Focal Length: D20 F150 mm

-

Vertical Focusing Range: ±10 mm

-

Light Spot Adjustment Range: Line 0–8 mm

-

Applicable Wavelength: 1070 nm

-

Max. Assist Gas Pressure: 15 bar

-

Weight: 0.7 kg

-

Product Size: 257 × 34 × 145 mm

Applications

The SUP23T is widely used in:

-

Metal fabrication – precise welding and cleaning of sheet metal parts

-

Automotive industry – cutting, repairing, and cleaning vehicle components

-

Kitchenware & home appliances – producing clean seams and polished finishes

-

Advertising & signage – flexible cutting and shaping of customized designs

-

Repair & maintenance – mobile and versatile for on-site work

Why Choose the SUP23T 4-in-1 Welding Head?

-

Combines welding, cleaning, cutting, and seam cleaning in one handheld tool

-

Lightweight and ergonomic, easy to operate for long shifts

-

High safety with integrated detection and alarm systems

-

Stable, strong, and clean weld seams with minimal spatter

-

Saves cost and workshop space by replacing multiple devices

TECHNICAL PARAMETERS

Additional information

| Fiber interface | QBH |

|---|---|

| Wavelength range | 1070±20nm |

| Rated power | ≤3000W |

| Focus length | 150mm |

| Focus adjustment range | -10mm~+10mm |

| Spot adjustment range | Line0-8mm |

| Auxiliary gas pressure | 15Bar |

| Cooling Method | Water Cooling |

| Weight | 0.75KG |

VIDEO

SAMPLE DISPALY

Send your messages to the supplier

Get additional product information or technical support. Our team is always available to provide you with the necessary guidance and solutions.