Laser cleaning technology has revolutionized industrial surface treatment by providing an efficient, non-contact, and environmentally friendly method for removing rust, paint, coatings, and contaminants. Among pulse laser cleaning machines, two primary laser beam types are widely used: Single-Mode (Gaussian Beam) and Multi-Mode (Flat-Top Laser Beam). Understanding their characteristics, advantages, and applications can help customers make informed decisions for their specific cleaning needs.

Single-Mode Laser Cleaning (Gaussian Beam)

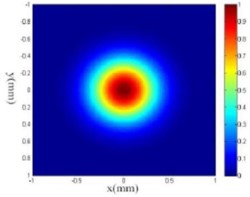

A single-mode laser beam features a Gaussian distribution, where the energy is highly concentrated in the center and gradually decreases outward. This unique energy profile creates a powerful and focused beam that is ideal for precision cleaning tasks.

Key Characteristics:

- High Energy Concentration: The center of the Gaussian beam has the highest intensity, allowing for deep and precise material removal.

- Better Stripping Ability: Due to its concentrated power, it can effectively strip away coatings, rust, and contaminants in a highly targeted manner.

- Faster and Detailed Cleaning: The beam’s sharp focus makes it more faster for delicate surfaces requiring controlled material removal.

- Efficient on Thin Layers: Works well on materials where a concentrated and controlled energy application is needed.

Best Applications:

- Cleaning precision components and electronic parts.

- Removing coatings from delicate surfaces such as aerospace or automotive components.

Performance Visualization:

As seen in the provided diagrams, the two-dimensional and three-dimensional representations of a JPT single-mode laser beam show a peak intensity in the center, confirming its Gaussian profile. This concentrated energy enables superior stripping capabilities and efficiency in precise cleaning applications.

Multi-Mode Laser Cleaning (Flat-Top Beam)

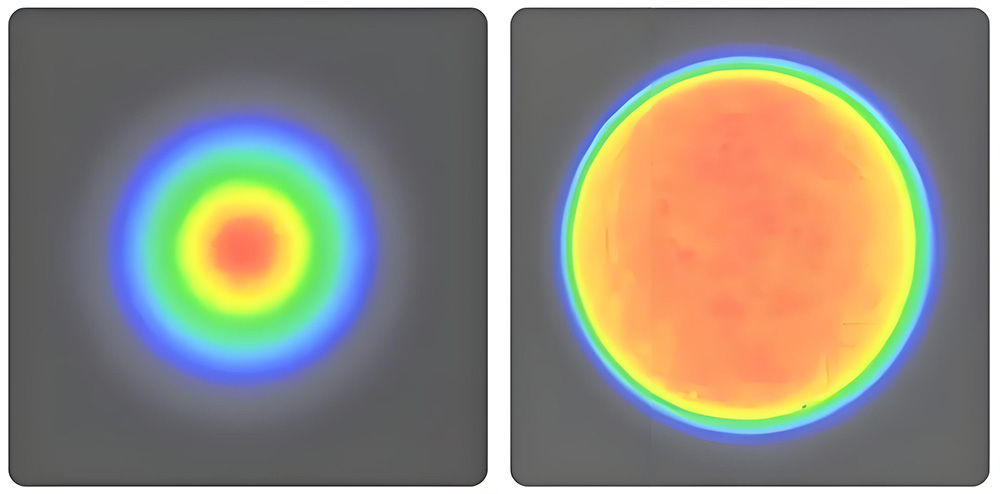

A multi-mode laser beam, also known as a flat-top beam, features a uniform energy distribution across its cross-section. Unlike the Gaussian beam, the irradiance is more evenly spread, making it gentler on surfaces while still maintaining effective cleaning performance.

Key Characteristics:

- Even Energy Distribution: The entire beam profile maintains a constant intensity, ensuring a uniform cleaning effect.

- Gentler on Substrates: With no energy peaks, this type of laser minimizes the risk of overheating or damaging the base material.

- Suitable for Large-Area Cleaning: Its broader energy coverage enables efficient cleaning over wide surfaces.

- Consistent Cleaning Quality: The even distribution results in a smooth and uniform cleaning effect across different materials.

Best Applications:

- Rust and oxide removal from thin metal layers without damaging the substrate.

- Industrial molds, tools, and fine engraving cleanup.

- Paint and oxide layer removal from metallic and non-metallic materials.

- Surface preparation for welding or coating applications.

- Removing contaminants from sensitive or heat-sensitive substrates.

Performance Visualization:

The comparison between Gaussian (single-mode) and flat-top (multi-mode) beams illustrates the key differences. A Gaussian beam has a peak intensity at the center, while the flat-top beam maintains a uniform energy distribution, making it more suitable for applications requiring gentler treatment.

Choosing the Right Laser for Your Needs

When selecting a pulse laser cleaning machine, it is crucial to consider the material type, cleaning requirements, and desired efficiency.

| Feature | Single-Mode (Gaussian Beam) | Multi-Mode (Flat-Top Beam) |

|---|---|---|

| Energy Distribution | Highly concentrated at the center | Evenly distributed across the beam |

| Stripping Ability | Stronger, precise removal | Moderate, uniform removal |

| Suitability for Thin Materials | Good | Excellent |

| Suitability for Surface Sensitive Areas | Less suitable | Highly suitable |

| Risk of Substrate Damage | Lower | Almost no have |

| Best For | Precision cleaning, electronics, fine rust, oil removal | For high requirements on substrate surface, such as molds and other precision equipment |

Conclusion

Both single-mode (Gaussian) and multi-mode (Flat-Top) pulse laser cleaning machines offer unique advantages. If your application requires high precision, deep stripping, and strong energy concentration, a single-mode laser is the ideal choice. On the other hand, if you need uniform, large-area cleaning with minimal substrate impact, a multi-mode laser provides superior performance.

Rayno Laser offers advanced pulse laser cleaning machines tailored to meet diverse industrial needs. Whether you require precision cleaning or broad-surface treatment, our single-mode and multi-mode laser solutions deliver optimal efficiency, reliability, and long-term cost-effectiveness.

For more details or consultation, contact us at Rayno Laser to find the perfect laser cleaning solution for your application!