A consistent airflow is crucial for efficient operation when using a handheld laser welding machine. Air helps cool the laser gun, protects the weld from contamination, and ensures high-quality welds. However, users often encounter issues such as no airflow, continuous airflow, or low airflow from the welding gun. These problems can severely impact the welding process and reduce overall efficiency. In this article, we’ll discuss the common causes behind these airflow issues and provide step-by-step solutions to resolve them.

Main Causes of Airflow Issues in Handheld Laser Welding Machines

- Gas Cylinder Issues: The gas cylinder may not be open, or it may be empty.

- Damaged Air Blow Port: The port responsible for releasing air may be burnt or damaged.

- Faulty Solenoid Valve: A malfunctioning solenoid valve may cause airflow problems.

- Continuous Airflow: Air continues to flow without being turned off.

- Airflow Blockage: Blockages in the air circuit can lead to insufficient airflow or no airflow at all.

Step-by-Step Solutions to Address Airflow Issues

1. Check the Gas Cylinder and Its Contents

Problem:

The most common issue when there is no airflow or weak airflow is a gas supply problem. The gas cylinder may not be open, or it may be empty.

Solution:

- Step 1: Verify that the gas cylinder valve is fully open.

- Step 2: Check the cylinder gauge to ensure there is gas remaining in the cylinder. If the gauge reads empty, replace the gas cylinder.

- Step 3: After confirming the gas supply, ensure that the hose is properly connected to both the gas cylinder and the machine. A loose connection may restrict airflow.

By addressing these points, you can rule out the possibility of an empty gas cylinder or an improperly opened valve, which are common culprits.

2. Inspect the Air Blow Port for Damage

Problem:

If there’s no airflow or intermittent airflow, it could be due to damage in the air blow port. This port is responsible for releasing air from the machine, which is crucial for protecting the weld and cooling the equipment.

Solution:

- Step 1: Inspect the blow port on the welding gun for visible damage. If it looks burnt or damaged, the port may need to be replaced.

- Step 2: If the port appears intact, proceed to check if the airflow is being properly directed. You can use compressed air to test the port and verify if it’s functioning correctly.

If the port is damaged, replacing it with a new part should resolve the airflow issue.

3. Test the Solenoid Valve

Problem:

A faulty solenoid valve can cause airflow issues. If the solenoid valve doesn’t open or close properly, it can prevent the gas from reaching the welding gun, leading to problems such as no airflow or continuous airflow.

Solution:

- Step 1: Access the solenoid valve and check the electrical connection.

- Step 2: Set the machine to manual air-blowing mode from the diagnostic interface. On the screen, click the “manual air-blowing” button to activate airflow.

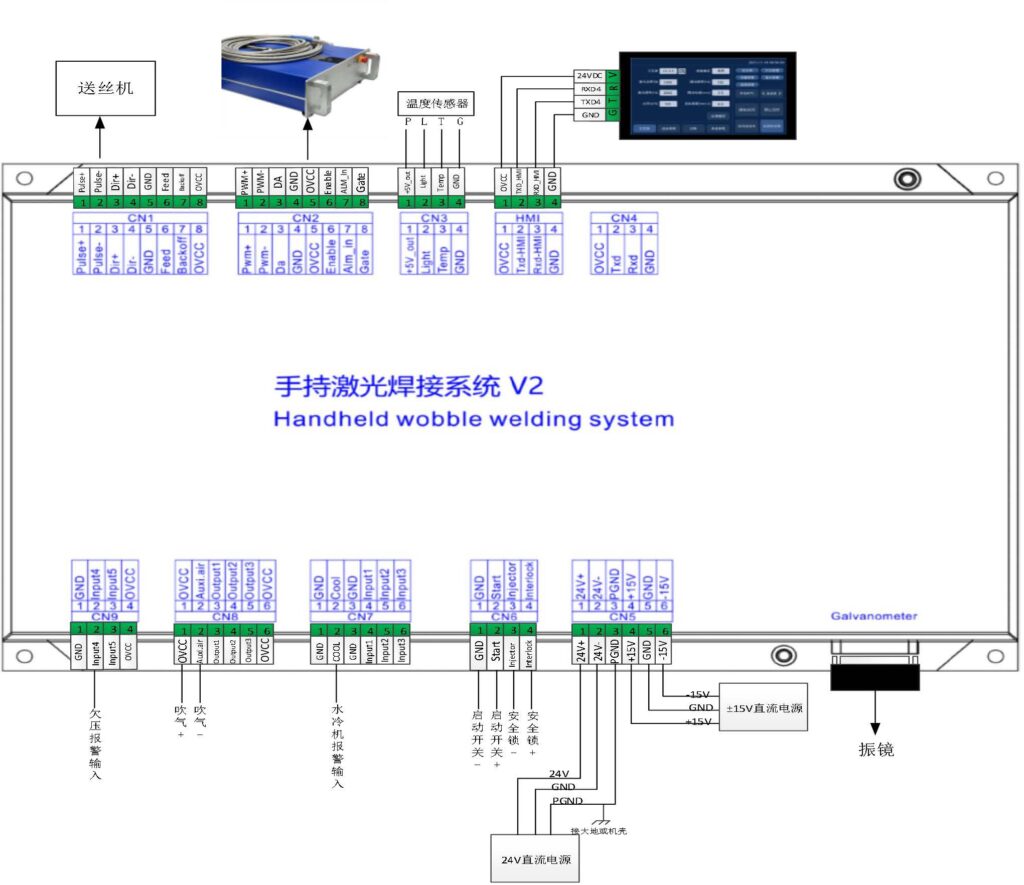

- Step 3: Using a multimeter, measure the voltage across pins 1-2 on the CN8 port. The expected voltage is 24V.

- If the voltage is absent, this indicates that the port is damaged, and the solenoid valve needs to be checked further or replaced.

- If the valve still doesn’t activate, it may be burnt out or defective, requiring replacement.

Testing the solenoid valve with a multimeter helps pinpoint if the solenoid is faulty or if the issue lies elsewhere.

4. Check for Continuous Airflow

Problem:

If air is continuously blowing even when it shouldn’t be, the problem could be with either the solenoid valve or the control box.

Solution:

- Step 1: First, ensure that manual air-blowing mode is not activated. Check the diagnostic interface to confirm that the system isn’t mistakenly set to continuous air mode.

- Step 2: Measure the voltage across pins 1-2 of the CN8 port in the control box when the system is not in air-blowing mode. If there is 24V, this indicates that the control box port is malfunctioning.

- Step 3: If the voltage is correct but the airflow remains constant, the solenoid valve may be unable to close, preventing the air from stopping. In this case, replace the solenoid valve.

In the case of continuous airflow, checking both the control box and the solenoid valve is crucial to identify the underlying cause.

5. Inspect the Entire Air Circuit for Blockages

Problem:

Low airflow or no airflow could be caused by blockages in the air circuit. These blockages can occur at various points in the system, including the gas cylinder, solenoid valve, hoses, and even the welding gun’s internal components.

Solution:

- Step 1: Start by checking the gas flow at the cylinder. If the flow is low, verify if the valve is fully open.

- Step 2: Check the solenoid valve output for any restrictions. You can measure the airflow through the valve by observing the air pressure or by using a flow meter.

- Step 3: Inspect the airline and welding gun hose for any kinks or blockages. Use compressed air to clear out any obstructions that might have built up over time.

- Step 4: If the airflow seems restricted after the solenoid valve, disassemble the gun’s airflow components and inspect them for internal blockages.

Clearing these blockages should restore normal airflow and prevent future issues from occurring.

Ask Support from Rayno Laser

Airflow issues in handheld laser welding machines are often the result of simple, fixable problems, such as an unopened gas cylinder, faulty solenoid valves, or damaged components. By following this troubleshooting guide, you can systematically identify and resolve these issues, ensuring that your machine functions properly and efficiently.

Maintaining proper airflow is essential for achieving high-quality welds and extending the lifespan of your welding equipment. Regular checks on components such as the gas supply, solenoid valve, and air circuit can prevent most common airflow issues and keep your machine running smoothly.

If these steps don’t resolve the problem, consider contacting a professional technician or the equipment manufacturer for further support.

2 Responses

I have the problem with my 3 n1 leser welding

When you bought this machine? What is the problem?