Table of Contents:

- What is a Laser Welding Robot?

- What Materials Can Laser Welding Robots Handle?

- Where Can Laser Welding Robots Be Used?

- Key Features of Our Laser Welding Robots

- Technical Specifications of the Laser Welding Robot

- Conclusion: How Laser Welding Robots Optimize Production

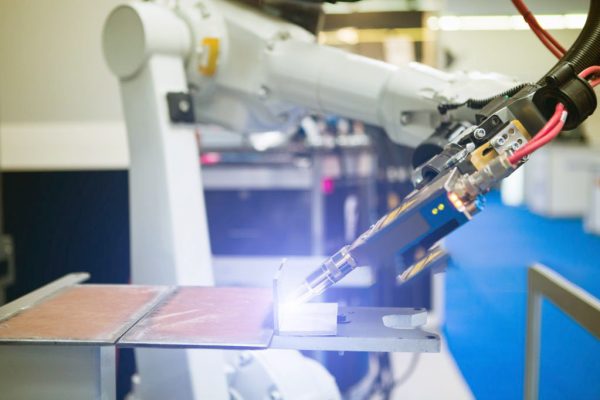

What is a Laser Welding Robot?

A laser welding robot is an advanced robot welding machine that uses a fiber laser to precisely weld various metals. Equipped with multi-axis robotic arms, like those from leading brands Fanuc, ABB, YASKAWA, and KUKA, these robots are designed for precise, automated welding operations. Laser robots bring unparalleled accuracy and speed to metal fabrication, drastically reducing the need for manual labor while ensuring consistent, high-quality welds every time.

Our laser welding robots are built for durability and ease of use. Unlike traditional welding equipment, they require minimal maintenance and can operate continuously for extended periods, making them perfect for high-demand manufacturing environments.

What Materials Can Laser Welding Robots Handle?

Laser welding robots are ideal for a variety of metals, providing reliable and clean welds without the need for additional finishing. These robots work seamlessly with:

| Material Type | Example Applications |

|---|---|

| Stainless Steel | Automotive, aerospace, household appliances |

| Carbon Steel | Structural components, machinery |

| Alloy Steel | High-stress environments, construction |

| Silicon Steel | Electric motors, transformers |

| Spring Steel | Tools, automotive springs |

| Aluminum & Alloys | Lightweight structures, electronics |

| Galvanized Steel | Outdoor equipment, protective coatings |

| Aluminum-Zinc Plate | Corrosive environments, outdoor structures |

By supporting such a diverse range of metals, our laser welding robots enable manufacturers to take on complex welding projects with ease. The machine’s flexibility makes it a powerful asset in industries with stringent material standards, like automotive and aerospace manufacturing.

Robot welding sample display-Cylindrical welding

Where Can Laser Welding Robots Be Used?

Laser welding robots are versatile enough to be used across various industries, thanks to their advanced capabilities and material compatibility. Here are some of the most common applications:

- Aerospace and Automotive Manufacturing

Laser welding robots provide the precision needed for critical components in these sectors, where quality and strength are essential. Their ability to handle high-strength steels, alloys, and lightweight metals makes them ideal for producing durable, lightweight structures. - Elevator and Machinery Manufacturing

In heavy-duty manufacturing, robot welding machines are used to create sturdy welds in structural components, which are crucial for performance and safety. - Medical Equipment

Robotics in medical equipment welding ensures precision and durability for parts that require minimal tolerances and high reliability. - Electronics and Household Appliances

Laser welding robots are capable of delicate welds on smaller components, perfect for electronics and household appliances that require compact, seamless welds for a clean finish. - Metal Fabrication and Custom Services

For metalworking businesses offering custom solutions, a robotic welding machine can be adapted for a variety of tasks, allowing for custom setups to meet unique specifications in metal part production.

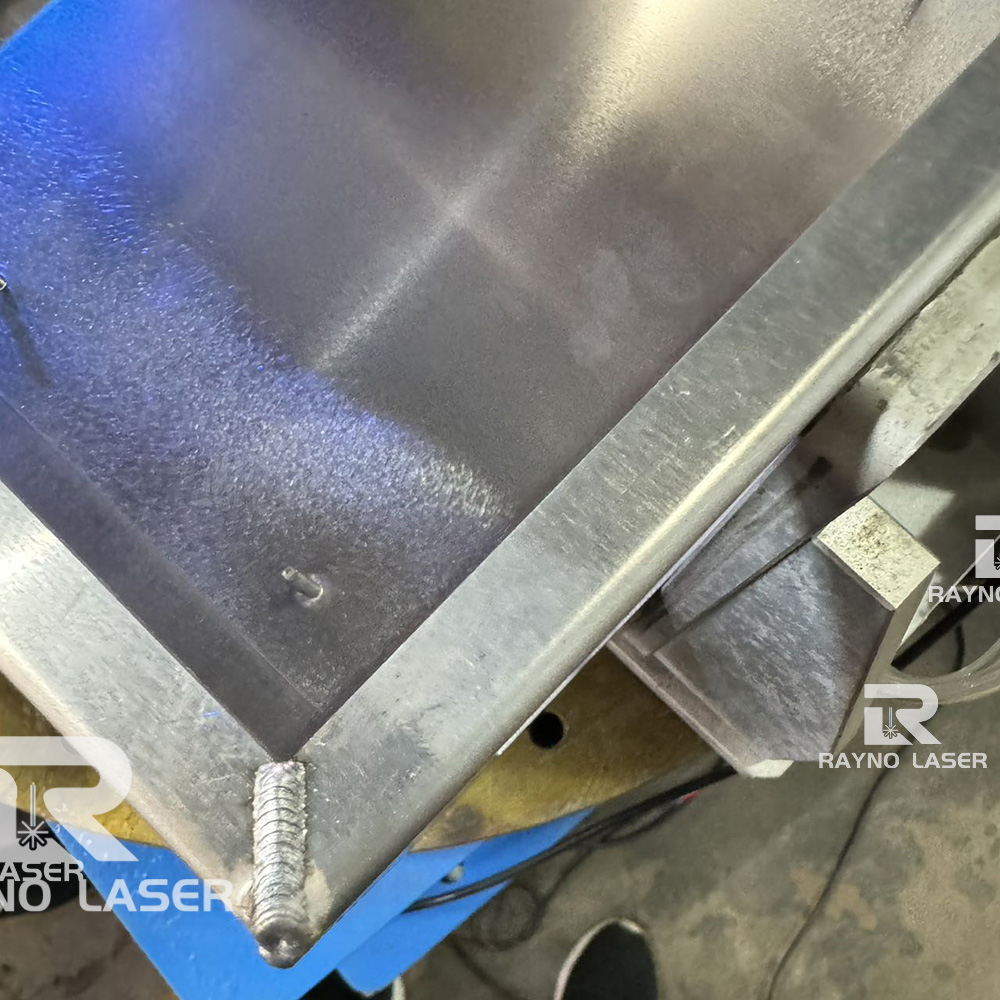

Robot welding sample display-Corner edge welding welding

Key Features of Our Laser Welding Robots

Each laser welding robot comes equipped with high-performance features designed to streamline production and ensure consistent quality:

- Flexible, Multi-Axis Robotic Arms

Our robots can perform complex welding operations at various angles. The multi-axis functionality, along with robotic arms from top brands like Fanuc and KUKA, allows for precise and versatile welding, even in hard-to-reach areas. - Fast Welding Speed with Minimal Heat Impact

The laser robot can achieve welding thicknesses of 0.5mm to 8mm, reducing heat distortion and ensuring that each weld is clean, smooth, and strong. This speed and accuracy are invaluable for high-throughput production. - Low Maintenance, No Consumables

Designed for efficiency, our robotic welders consume a fraction of the energy used by traditional YAG and arc welders. With no consumables and a 100,000-hour lifespan, these robots minimize operational costs while maximizing productivity. - User-Friendly and Labor-Saving

Simple to operate, our welding robots allow companies to reduce manual labor and streamline their production line. This helps businesses save on labor costs while enhancing workplace safety and efficiency.

Robot welding sample display-Outside corner welding

Technical Specifications of the Laser Welding Robot

Our laser welding robots are optimized for a wide range of production needs. Here’s an overview of the key specifications:

| Specification | Details |

|---|---|

| Laser Wavelength | 1070 ± 10 nm |

| Working Mode | Continuous/Pulse |

| Recommended Welding Thickness | Stainless/Carbon Steel: 0.5-8 mm |

| Welding Gap Requirement | < 0.5 mm |

| Repeat Positioning Accuracy | ± 0.05 mm |

| Aiming Positioning | Red Light Indicator (CCD optional) |

| Total Equipment Power | 5-20 KW |

| Operating Voltage | AC220V/380V, 50-60 Hz |

| Power Options | 1000-4000 W |

| Spot Size | 0.2-5 mm (Adjustable) |

| Robotic Arm Length | 930 mm (Customizable) |

| Work Table | Customizable |

These technical features give our welding robots the adaptability to perform precisely in diverse production environments, supporting the most exacting manufacturing standards.

Conclusion: How Laser Welding Robots Optimize Production

Integrating laser welding robots into your production line can dramatically improve productivity, accuracy, and cost savings. With flexible capabilities and compatibility with advanced robotic arms from Fanuc and ABB, our robot welding machines cater to the needs of modern industry. From aerospace to custom metal fabrication, these robots are optimized for today’s most demanding welding applications.

For more details about the advantages of robotic welding and how a robot welder can benefit your specific manufacturing needs, contact us to discuss tailored solutions and learn how you can revolutionize your production with cutting-edge laser robots.