Introduction

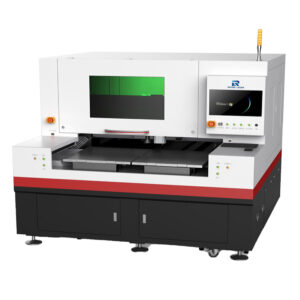

In advanced glass manufacturing, picosecond infrared laser cutting machines are widely recognized for their ability to create ultra-smooth edges with minimal heat-affected zones. However, many customers wonder why these machines often include a CO₂ laser system as part of the process.

The combination of a picosecond laser and CO₂ laser is not redundant—it’s a highly efficient, complementary system that ensures both precision and clean separation of the glass. Below, we explain the principle, purpose, and effect of adding CO₂ laser technology to picosecond glass cutting.

Principle of Picosecond Laser Cutting

A picosecond laser delivers ultra-short pulses (trillionths of a second) with extremely high peak power. When focused on glass:

- The laser modifies the internal structure of the glass without creating large thermal stress.

- It creates a narrow “modified line” inside the glass, which defines the cutting path.

- This process leaves no cracks, microchips, or rough edges compared to mechanical cutting.

However, after the glass is internally modified, the material is not fully separated. It still requires a controlled way to “split” or “separate” along the modified path.

Why Add a CO₂ Laser System?

1. Controlled Thermal Stress Splitting

A CO₂ laser emits infrared light at a wavelength of 10.6 µm, which glass strongly absorbs. When the CO₂ laser locally heats the glass along the picosecond laser’s modification line:

- The thermal expansion and contraction cause a controlled crack propagation, effectively separating the glass along the desired path.

- This splitting is highly precise and does not generate chips or roughness.

2. Increased Cutting Speed

Without a CO₂ laser, mechanical force (like applying pressure) would be needed to break the glass along the modification line, which is slower and riskier.

- The CO₂ laser automates and speeds up the splitting, making the overall cutting process faster and more efficient.

3. Improved Edge Quality

The CO₂ thermal splitting step ensures that the glass breaks cleanly and smoothly, maintaining the high edge quality that picosecond lasers are known for.

- No polishing or secondary finishing is required.

The Working Process: Step by Step

- Modification – The picosecond laser scans the cutting path inside the glass, creating a series of microscopic modifications.

- Splitting – The CO₂ laser follows the same path, applying localized heating to induce thermal stress.

- Separation – The glass separates cleanly along the modified line, resulting in perfectly smooth edges.

Effects and Benefits

- Smooth, chip-free edges that meet high-end requirements for display glass and optical glass.

- Reduced post-processing costs—no grinding or polishing needed.

- High throughput—fast cutting with consistent quality.

- Lower breakage rate—controlled splitting reduces material waste.

Applications

This dual-laser approach is commonly used in:

- Smartphone and tablet cover glass production

- Automotive display panels

- Optical glass cutting

- Thin and brittle specialty glass

FAQ: Picosecond + CO₂ Laser Cutting

1. Can a picosecond laser cut glass without a CO₂ laser?

Technically, yes, but the glass would need mechanical breaking after modification, which risks cracks and chips. Adding a CO₂ laser ensures clean, automated splitting.

2. Does this process work for tempered glass?

No, physically tempered glass cannot be cut after tempering—it will shatter due to internal stress. The correct process is cut first, then temper.

3. Why use a dual-laser system instead of mechanical cutting?

Dual-laser cutting eliminates tool wear, edge chipping, and uneven cuts, offering higher precision and lower long-term cost.

4. How smooth are the edges after cutting?

The combination of picosecond + CO₂ lasers creates polished-like edges with no need for grinding or secondary finishing.

5. What glass thicknesses can be processed?

Picosecond + CO₂ laser systems can handle a wide range of glass thicknesses, from ultra-thin display glass to several millimeters thick, depending on the machine configuration.

Summarize

The CO₂ laser system is an essential partner for the picosecond glass laser cutting machine. While the picosecond laser defines the cutting path with unmatched precision, the CO₂ laser ensures clean separation and optimal edge quality. This combination achieves the perfect balance of speed, accuracy, and cost-effectiveness for modern glass manufacturing.